The Electric Vehicle Revolution and the Future of Automotive Plastics

The automotive industry is in the midst of a transformative shift. One of the most significant markers of this shift is the swift rise of electric vehicles (EVs).

The transition away from traditional internal combustion engines (ICE) is driven by several factors, among them being:

- Growing support for decarbonization: Environmental concerns are pushing the industry towards cleaner technologies

- High fuel prices: Rising fuel costs make EVs a more attractive option for consumers

- Government regulations: Policy changes and deadlines for phasing out ICE vehicles are accelerating the EV adoption rate

This shift necessitates a complete rethinking of car manufacturing. New components, technologies, and production methods are required for EVs.

Additionally, with EV range anxiety being a major concern, lightweighting automotive components becomes paramount to optimizing battery performance and maximizing range. This is where innovative materials like advanced plastics come into play.

At the same time, automotive manufacturers might be hesitant to adopt new, unfamiliar materials. The safety-critical nature of the automotive industry demands rigorous testing and proven performance. Therefore, the lack of extensive data on the behavior of new plastics can be a barrier to their adoption.

Despite the challenges, the future of automotive plastics is bright. The increasing demand for EVs creates a vast market for lightweight, high-performance materials. Plastics manufacturers who embrace innovation and collaborate with automakers to develop and validate new EV-specific plastics are well-positioned to thrive in this evolving landscape.

The Rise of Electric Vehicles: A Market Poised for Takeoff

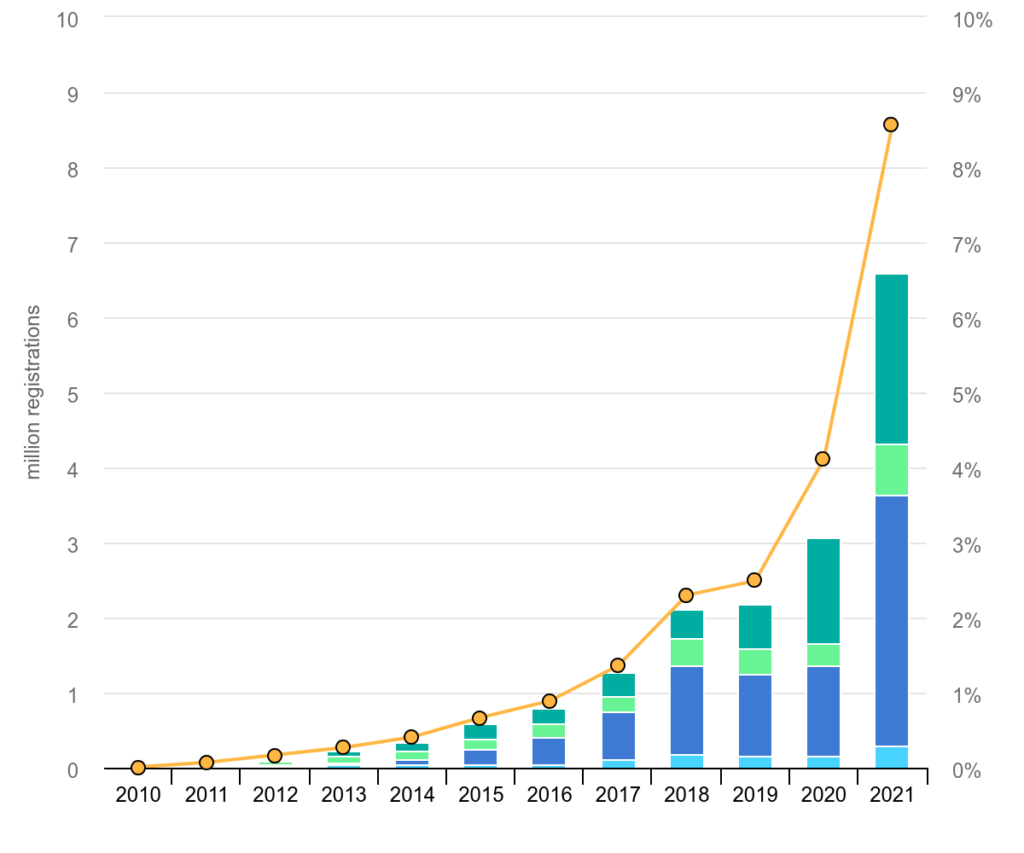

The electric vehicle (EV) market is experiencing explosive growth. Statistics paint a clear picture of this accelerating trend. From 2017 to 2022, global EV sales skyrocketed from about 1 million to over 10 million.

According to KPMG’s report on the ‘Future of Automotive’, by 2030 it is estimated that half of the car sales in the U.S could be EVs. Additionally, the report states that, according to Chinese officials, 70% of China’s automobile sales will be electric by 2030.

Several key factors are fueling this electric revolution.

Growing Support for Decarbonization

Concerns about climate change and the need to reduce greenhouse gas emissions are driving a global push towards cleaner transportation solutions. EVs offer a significant advantage here, producing zero tailpipe emissions and contributing to a greener future.

This sentiment is echoed in ambitious policy initiatives like the European Union’s “Fit for 55” plan, which aims for a 55% reduction in net emissions by 2030. The automotive industry is a key player in achieving such goals, and EVs are positioned as a leading technology in this fight against climate change.

High Fuel Prices

The recent surge in fuel costs has significantly impacted consumer behavior. EVs offer a more cost-effective alternative in the long run, as electricity prices tend to be more stable than gasoline prices. This economic advantage is becoming increasingly attractive to drivers.

Government Actions Promoting EV Adoption

Governments worldwide are encouraging the transition to EVs by implementing various incentive programs. These initiatives often include tax breaks, subsidies, and rebates for EV purchases, making them more affordable for consumers. Additionally, some countries are setting ambitious deadlines to phase out the sale of new gasoline-powered vehicles altogether.

These policy measures create a clear and targeted push towards widespread EV adoption.

Policy Regulations Pushing EV Development

Beyond incentives, governments are implementing regulations that directly influence and accelerate EV development. The aforementioned “Fit for 55” package from the EU serves as a prime example. This comprehensive plan outlines various measures to promote clean energy technologies, including stricter emission standards for automakers, which in turn incentivizes the production of more EVs.

Similar regulations are being enacted in other regions around the globe, all contributing to a global push towards a future dominated by electric vehicles. For instance, in the U.S., the Environmental Protection Agency set forth new regulations calling for 56% of all new vehicles to be electric by 2032.

The combined effect of these factors – environmental concerns, economic considerations, and government support – is creating a powerful force propelling the EV market forward.

The New Production Landscape for Plastics: Embracing Lightweighting and Innovation

The surge in electric vehicles (EVs) is sending ripples through the entire automotive industry, and plastics manufacturers are no exception. The traditional production standards for gasoline-powered vehicles are no longer sufficient for the unique demands of EVs.

A key difference lies in range anxiety. Unlike gasoline vehicles with readily available refueling options, EVs rely on battery power. Therefore, maximizing an EV’s range becomes a top priority for automotive manufacturers. This results in the need for lightweighting automotive components. Every kilogram shed from a vehicle’s weight translates to increased battery efficiency and ultimately, a greater driving range.

Here’s where innovative plastics become significant. Traditional material like steel may be robust, but they also add considerable weight to a vehicle. Advanced plastics, however, present strength, low weight, durability, and design flexibility.

By utilizing these materials strategically in automotive components – such as body panels, fenders, interior parts, or structural components – manufacturers can achieve significant weight reduction without compromising on safety or performance.

However, innovation does not stop at the material itself. Manufacturing innovation also takes shape in the form of advanced manufacturing through the use of techniques like automation, robotics, Industrial Internet of Things (IIoT), and more.

With the combination of innovative materials and techniques, plastics manufacturers can become key partners in the development of next-generation EVs.

Challenges and Opportunities for Plastics Manufacturers

While the shift towards EVs presents a great opportunity for plastics manufacturers, it also comes with its own set of challenges.

One of the biggest hurdles lies in the limited data available on the behavior of new plastics materials. Unlike traditional materials with a long history of use in automotive manufacturing, new, innovative plastics have not undergone years of rigorous testing and real-world use.

Therefore, the lack of data on material behavior can raise concerns regarding potential quality or safety issues when implementing the materials in critical car components.

These challenges, however, can be transformed into opportunities for plastics manufacturers.

For instance, embracing technologies that offer real-time, in-mold process control can enable manufacturers to gain valuable insights into the behavior of new plastics during the production process. This allows for dynamic process adjustments and optimizations to ensure the consistent quality and performance of the final product.

Those who embrace innovation and overcome these challenges stand to reap significant benefits, including:

- Increased market share in the growing EV sector: As the EV market continues to expand, plastics manufacturers who can provide lightweight, high-performance materials will be well positioned to capture a significant share of this burgeoning market.

- Building a reputation for sustainability: Lightweight plastics play a critical role in reducing the overall weight of EVs, which in turn leads to increased range and lower emissions. Manufacturers who champion sustainable solutions will not only appeal to environmentally conscious consumers but also position themselves favorably with automakers seeking to build cleaner, greener vehicles.

The future of automotive plastics hinges on the ability to adapt and innovate. By addressing the challenges of limited data and safety concerns, plastics manufacturers have the potential to become key players in the electric vehicle revolution, shaping the future of sustainable transportation.

Interested in learning more about automotive plastics manufacturing? Read our free white paper ‘Investigating Automotive Plastics Manufacturing’.