Global Plastics Material Trends in 2024

The plastics industry stands as a formidable economic force, with the global market value reaching 712 billion USD in 2023.

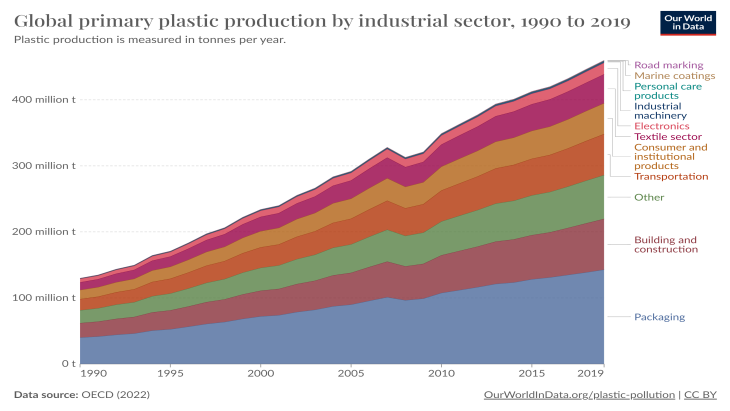

This industry’s extensive applications in critical sectors such as automotive, aerospace, construction, packaging, and healthcare underscore its integral role in global economic growth and innovation. Among these achievements, the plastics industry is experiencing rapid transformation spurred by shifting market demands, technological advancements, and an escalating focus on environmental concerns.

In this article, we investigate the key trends defining the current plastics material landscape. Specifically, we address the interrelationship between plastics market growth, shifting customer demands and preferences, sustainable plastics production, and advanced materials and new technologies.

Global Plastics Market Growth: An Outlook

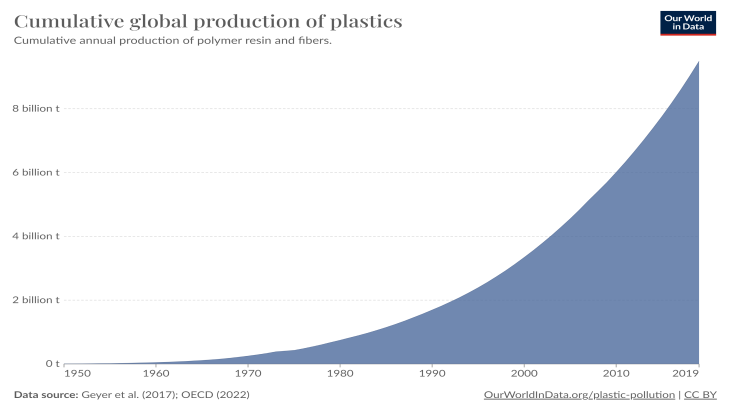

The global plastics market is projected to maintain a steady growth trajectory, reaching a value of over 1.05 trillion USD by 2033, guided by a combination of factors including:

- Population Growth and Urbanization: The global population is expected to reach 9.7 billion by 2050, with urbanization rates continuing to rise. This demographic shift will lead to increased demand for polymer-based products in various sectors, including infrastructure development, packaging, and consumer goods.

- Rising Disposable Incomes: As economies develop and disposable incomes increase, consumers are more inclined to purchase products made from plastics, which offer a range of benefits, including durability, versatility, and cost-effectiveness.

- Technological Advancements: Innovation in polymer synthesis, material processing, and recycling technologies is continuously pushing the boundaries of what is possible with plastics, leading to the development of new and improved products with enhanced properties and applications.

Sustainability: A Key Challenge and Opportunity

The plastics industry is facing increasing scrutiny over its environmental impact, particularly in terms of plastic pollution. This has led to a growing demand for sustainable plastics, which are derived from renewable sources or engineered to biodegrade under specific conditions.

Bio-based Plastics

Bio-based plastics, derived from renewable resources such as plants, algae, and bacteria, are gaining traction as an eco-friendly alternative to traditional petroleum-based plastics. These plastics offer similar properties to their conventional counterparts but have a lower environmental impact.

Biodegradable Plastics

Biodegradable plastics are designed to break down into harmless organic matter under specific conditions, such as exposure to microorganisms or certain environmental factors.

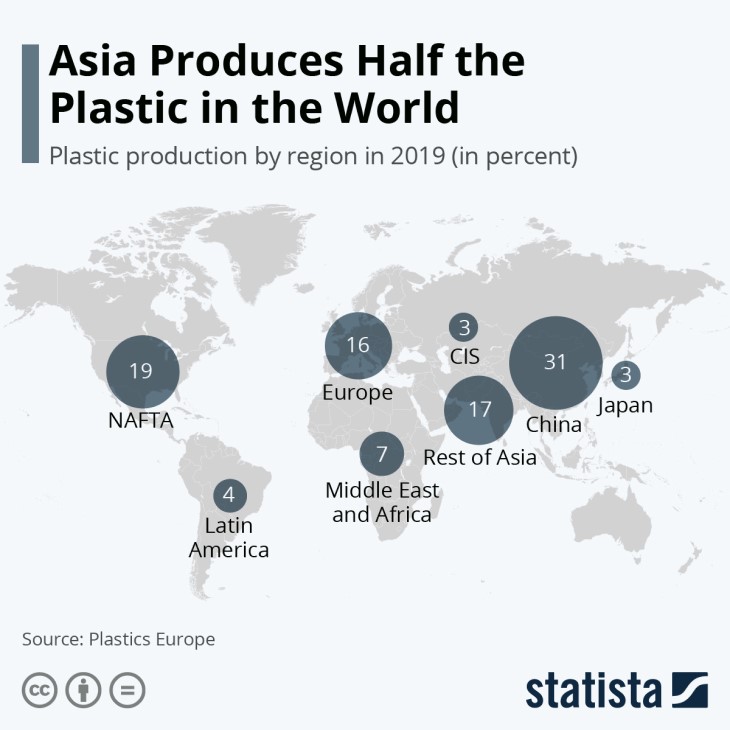

Regional Dynamics: Asia-Pacific at the Forefront

Asia-Pacific is the undisputed leader in the global plastics market, accounting for over 40% of consumption. This dominance is driven by factors such as rapid economic growth, urbanization, and rising disposable incomes in the region.

China is the world’s largest producer of plastics, accounting for roughly 32% of global production in 2021. The country’s vast manufacturing base and strong economic growth have fueled demand for plastics across various industries.

North America (NAFTA) is the second-largest producer of plastics, with the United States being the dominant market. The region’s advanced manufacturing capabilities and technological innovations continue to drive growth in the plastics sector.

Europe is a key center for plastics research and development, with a focus on sustainable and high-performance materials. The region’s stringent environmental regulations are also driving innovation in eco-friendly plastics solutions.

Shifting Customer Demands and Preferences

The plastics industry is undergoing a profound transformation driven by a realignment of customer demands and preferences. As consumers become increasingly aware of environmental and sustainability issues, they are seeking products that align with their values and contribute to a more sustainable future.

A 2023 study by NielsenIQ found that 73% of consumers globally are willing to pay more for sustainable products. This shift is evident in the growing popularity of eco-friendly brands and the increasing demand for products made from recycled materials.

The plastics industry is responding to these evolving customer preferences by developing innovative materials and processes that minimize environmental impact, enhance recyclability, and promote circularity throughout the product lifecycle.

Industry’s Response to Customer Demands

In 2021, the Ellen MacArthur Foundation released a report outlining a roadmap for a circular economy for plastics. The report calls for a transition from a linear economy, where materials are extracted, used, and then disposed of, to a circular economy, where materials are kept in use for as long as possible and then recovered and regenerated at the end of their useful life.

The plastics industry is embracing this shift by developing bio-based and biodegradable plastics. The industry is also working to improve the recyclability of plastics. This includes developing new technologies for sorting and processing mixed plastics, as well as creating new products from recycled materials.

Eco-friendly and Regulation-compliant Materials

Meeting the demands of eco-conscious consumers necessitates a focus on developing eco-friendly materials. Additionally, complying with stringent environmental regulations is crucial for maintaining market access and building trust with customers.

The European Union (EU) has implemented a number of regulations aimed at reducing the environmental impact of plastics, including the Single-Use Plastics Directive, which bans the production and sale of certain single-use plastic items such as straws and cutlery.

The United States is also considering new regulations on plastics, including a ban on certain single-use plastics and requirements for recyclability.

Relevant Read:

Green Compliance in Plastics Manufacturing: CSRD in 2024

Advanced Materials and New Technologies

The plastics industry is at the forefront of material innovation, constantly developing new materials and technologies to meet the evolving needs of customers and address sustainability concerns. One of the key areas of focus is the development of high-performance polymers that possess superior properties such as strength, flexibility, and resistance to extreme conditions.

High-performance Polymers: Enhanced Material Properties

High-performance polymers are revolutionizing various industries, offering unparalleled performance and enabling the creation of innovative products. These polymers are tailored to specific applications, ranging from lightweight automotive components to durable medical implants.

Polymer nanocomposites, which combine polymers with nanoscale fillers, are one example of high-performance polymers that are gaining traction. These nanocomposites offer improved strength, stiffness, and barrier properties compared to conventional polymers.

Functionalized Plastics with Embedded Additives

Functionalized plastics are gaining traction as a means of enhancing manufacturing outcomes and tailoring materials to specific requirements. Embedded additives with specialized functionalities, such as self-healing, antimicrobial protection, or optical transparency, are enabling new levels of performance and customization.

One example of a functionalized polymer is self-healing polyurethane, which can automatically repair small cracks and damage. This technology has potential applications in a variety of industries, including automotive, construction, and consumer goods.

Smart Plastics: Integration of Sensors and Electronics

Smart plastics represent a transformative advancement in materials technology, combining the functionality of plastics with the intelligence of electronics. Embedding sensors and electronics into polymers opens up new possibilities for applications such as self-regulating temperature control, active packaging, and wearable electronics.

For example, intelligent packaging can be used to monitor food freshness and prevent spoilage. Smart textiles can be used to track health data and provide real-time feedback to wearers.

Conclusion

The plastics industry is at a critical juncture, facing the dual challenges of meeting evolving customer demands and addressing environmental concerns. By embracing innovation, prioritizing sustainability, and staying informed of new technologies, the industry can position itself for long-term success and contribute to a more sustainable future.

The industry’s ability to adapt and innovate will be crucial in meeting the demands of the future. By developing new materials, processes, and technologies, the plastics industry can continue to play a vital role in the global economy and help to create a more sustainable future for all.