The Historical Evolution and Industrial Transformation of DEA by NETZSCH and sensXPERT

In today’s fast-paced industrial environment, particularly within the plastics and composites manufacturing sectors, ensuring product quality and optimizing manufacturing processes are essential. Manufacturers in these fields face unique challenges, such as precisely controlling material properties and promptly responding to process variations. Advanced measurement techniques are crucial to maintaining competitive advantage and operational efficiency in such cases.

Dielectric analysis (DEA) is a critical tool in this context. DEA is a powerful technique that measures the dielectric properties of materials, such as permittivity and conductivity, as they cure or undergo phase transitions. These properties provide valuable insights into the molecular dynamics and structure of the materials, making DEA an indispensable tool for characterizing and optimizing the curing processes of plastics and composites.

Traditional DEA techniques are primarily confined to laboratory settings, where they offer high precision and reliability. Such measurements are often conducted using dielectric spectroscopy performed by network analyzers or LCR meters with low data acquisition rates. However, modern manufacturing processes’ dynamic and fast-paced nature necessitates more agile solutions that provide real-time material data, enabling immediate process adjustments and in-process quality control. This is where sensXPERT has made a groundbreaking impact.

By leveraging NETZSCH’s high-precision laboratory measurement techniques, sensXPERT, a NETZSCH Group venture, transformed these principles into real-time, practical solutions for in-process quality control and dynamic process adjustments. This transformation enables plastics and composites manufacturers to seamlessly integrate advanced DEA measurements and real-time data analytics into their production lines, thus enhancing product quality, reducing waste, and improving overall process efficiency.

This article delves into the history and evolution of DEA, exploring how it transitioned from a purely laboratory-based technique to a vital tool in modern manufacturing. We will examine the collaborative efforts of NETZSCH and sensXPERT to overcome the challenges of in-process characterization, the industrial applications of DEA, and the future trends that promise to revolutionize the manufacturing landscape further. By tracing the development and implementation of DEA technology, we aim to highlight its profound impact on the plastics and composites industries, showcasing its role in driving innovation and excellence.

Fundamentals of Dielectric Analysis (DEA)

Dielectric analysis (DEA) is a sophisticated measurement technique used to assess the dielectric properties of materials, specifically their permittivity and conductivity, as they undergo various physical and chemical changes, such as curing or phase transitions. The fundamental principle of DEA involves applying an alternating voltage to a material and measuring its response in terms of the resulting current and the phase shift between the voltage and current. In short, it penetrates the material with an electric voltage and measures the time it needs to respond. This response is influenced by the material’s molecular structure and dynamics, providing valuable insights into its behavior and properties.

Key Concepts in DEA:

- Permittivity (ε): This measures how much electric field the material can store. It provides insights into the material’s ability to be polarized by an electric field, which is crucial for understanding molecular interactions and structural changes.

- Conductivity (σ): This measures the material’s ability to conduct electric current. It is directly related to the mobility of charge carriers within the material, indicating the progress of curing or other chemical processes.

- Phase Transitions and Curing Processes: DEA is particularly valuable for the in-process monitoring of phase transitions (e.g., from liquid to solid) and curing behavior in polymers and composites. It can track the entire process in real time, offering precise control over manufacturing conditions.

Historical Background of DEA

The history of dielectric analysis (DEA) at NETZSCH and sensXPERT is marked by significant developments and advancements that have transformed it from a laboratory-based technique into a critical component for contemporary manufacturing processes. This journey highlights the dedication and innovation that have driven DEA’s evolution, making it an indispensable technology in the plastics and composites industries.

Here is a detailed timeline of its evolution:

- 1980s: The foundational development of DEA technology took place at the Massachusetts Institute of Technology (MIT) in Boston, driven by the pioneering work of David D. Day. His efforts laid the groundwork for understanding and utilizing dielectric properties to analyze material behavior.

- 1982: Micromet Instruments was founded as a spin-off from MIT, aiming to commercialize DEA technology. This company played a crucial role in DEA’s early adoption and industrial application.

- 1986: The DEA measurement principle was licensed to DuPont Instruments. This collaboration was instrumental in expanding the reach of DEA. However, DuPont Instruments, which later became TA Instruments, eventually discontinued DEA around 2010, leading to a pivotal shift in the technology’s journey.

- 2001: Micromet Instruments underwent two acquisitions before being acquired by NETZSCH Analyzing & Testing. This acquisition marked a significant milestone, as NETZSCH began to develop and refine DEA technology further.

- 2009: Marco Zier joined NETZSCH and started working on re-developing the DEA230/10 and DEA231 models on a new technical platform. This redevelopment aimed to enhance the technology’s robustness and applicability in various industrial settings.

- 2012: NETZSCH Analyzing & Testing launched the DEA288 Epsilon, setting a new standard for thermoset cure monitoring. This advanced device incorporated state-of-the-art features, significantly improving accuracy and reliability in industrial applications.

- From 2012 onwards: NETZSCH focused on pushing DEA into critical applications, including carbon fiber composite production.

- From 2013 onwards: Marco Zier performed early trials with coated in-mold sensors, working with high-profile customers such as BMW. This collaboration aimed to bring transparency into and optimize the curing of carbon fiber composite components for the BMW i3 series, demonstrating DEA’s applicability in demanding environments. At the same time, Dr. Alexander Chaloupka, in collaboration with NETZSCH Analyzing & Testing, focused on applying DEA to plastics manufacturing at Fraunhofer. This period saw efforts to correlate DEA results with laboratory testing standards, expanding the technology’s scope to include thermoplastics and elastomers.

- 2016: Alexander Chaloupka officially joined NETZSCH Analyzing & Testing. Along with Marco Zier and some other colleagues, Dr. Chaloupka continuously pushed the limits of DEA measurement principles, driving innovation and application in diverse industrial contexts.

- March 2018: The DEA288 Ionic was launched, featuring the first commercially available sensor capable of direct contact with plastics reinforced with electrically conductive fillers or polycondensating materials. Its presentation at the JEC 2018 in Paris included live demonstrations garnering significant attention and validation from the composite industry.

- June 2018: NETZSCH Analyzing & Testing initiated their business field, ‘Process Analytics’, to further market DEA. Within two years, this initiative saw massive turnover, spreading DEA technology globally and solidifying its industrial relevance.

- September 2019: The concept of sensXPERT was born, targeting the further development of DEA from purely a measurement technology to an integrated solution for series manufacturing processes. This vision aimed to embed DEA into real-time production environments, enhancing operational efficiency and quality control.

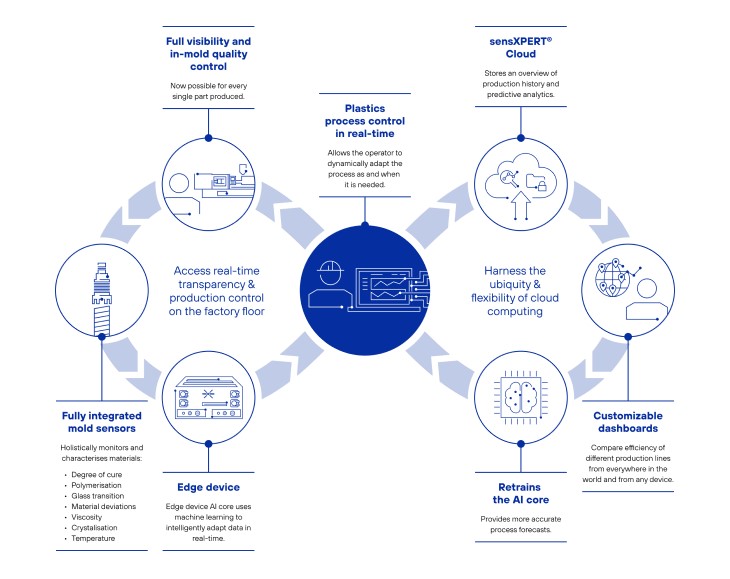

- 2020: The sensXPERT concept received funding from NETZSCH shareholders, leading to the creation of the first minimum viable product. This product was capable of real-time communication with manufacturing machines, integrating material kinetics with in-mold material behavior through machine learning models.

- July 2021: NETZSCH Process Intelligence GmbH, the company behind the sensXPERT brand, was founded. This establishment marked a new era in the evolution of DEA, underscoring the commitment to integrating advanced DEA solutions into industrial processes.

- November 2022: sensXPERT won the Innovation Award from the Federation of Reinforced Plastics (AVK) for its pioneering plastics and composite process optimization solution. This accolade recognized the significant impact of sensXPERT’s advancements in the field, highlighting its role in driving innovation and efficiency in manufacturing.

- July 2023: In the past three years of sensXPERT’s existence, the team has taken the initial product and pushed it to new heights. They have worked tirelessly to develop the DEA solution into something more advanced and adaptable for various industrial applications. Additionally, the team is involved in upcoming new projects, promising to bring further innovations and enhancements to the manufacturing sector.

Through these milestones, DEA evolved significantly, driven by continuous innovations and collaborative efforts, primarily by NETZSCH and sensXPERT. The technology’s journey from laboratory research to a critical industrial tool highlights its transformative impact on the plastics and composites manufacturing industries.

Lab-to-Manufacturing Transition

The journey of adapting dielectric analysis (DEA) from laboratory to manufacturing environments is marked by overcoming significant challenges. Dr. Alexander Chaloupka, Managing Director at sensXPERT, points out that laboratory measurements often fall short in replicating the real-life conditions that materials experience:

“The problem with the laboratory measurement technologies is that you always measure information from the momentum of the material. So, you have one batch of material usually in a secured environment, even if you characterize several batches in the lab, you are not able to really measure a material in a condition that it really sees in real life.”

Manufacturing processes involve variations due to transportation, storage, and treatment – even within the machines – which are not easily replicated in lab conditions. Dr. Chaloupka further explains the difficulty in translating lab data to manufacturing settings, stating, “Even if you do a lot of trial-and-error measurements in the lab, nobody has been able to really transfer the data you create in the lab one-on-one to the manufacturing without the need for further tuning.”

NETZSCH and sensXPERT tackled this issue by developing a DEA solution capable of operating under dynamic manufacturing conditions. Marco Zier, Director of R&D at sensXPERT, describes their innovative approach: “The standard thing with dielectrics is that it is usually just used in lab environments, sometimes in very specialized lab environments, and we bring it to the production floor in all this rough environment where usually no dielectric equipment is used.” Ensuring the technology could endure industrial conditions required significant innovation.

Innovating DEA: Enhancing Durability and Material Compatibility

Adapting dielectric analysis (DEA) for industrial use required addressing several critical factors: durability, material and sensor development, and overcoming various challenges like automated data analysis. The journey to integrate DEA into manufacturing processes is a testament to the innovative efforts of NETZSCH and sensXPERT.

Durability and Industrial Applications

One of the primary considerations in transitioning DEA to industrial settings was ensuring the technology’s robustness and durability. In high-temperature environments, such as those found in automotive and aerospace applications, the equipment needed to withstand prolonged exposure to extreme conditions.

Dr. Alexander Chaloupka reflects on this:

“When I started my journey more than ten years ago with dielectric analysis technology, I looked into several technologies like temperature measurements, pressure measurements, dielectrics, ultrasound, and thermography. But when it comes to generating insights into material behavior and phase transitions and correlating it to post-process quality control parameters like dimensional stability, degree of cure, and mechanical stability, dielectrics was the choice.”

The durability of DEA under harsh conditions made it the preferred choice over other technologies like ultrasound, which faced issues such as the rapid aging of piezoelectric systems at high temperatures.

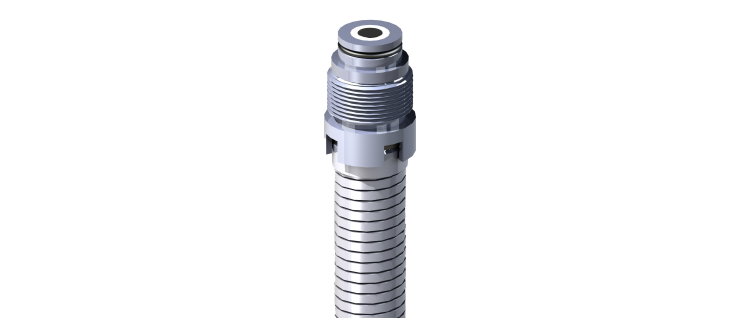

Materials and Sensor Development

Working with materials such as carbon fiber-reinforced plastics posed additional challenges. These materials, with their electrically conductive fillers, typically led to short circuits in traditional DEA setups. Dr. Chaloupka explains the innovative approach they took to overcome this hurdle:

“We had to work with carbon fiber reinforced plastics, so plastics with electrically conductive fillers inside because the dielectric measurement principle usually is not made for it. Because in the principle we have the two electrodes, once you place something electrically conductive on top of it, you have a short circuit, then you measure nothing. That was another struggle we had, and we were actively working on the absolute value calibration and on the coated sensors. We made great progress.”

The development of coated sensors was a breakthrough, allowing accurate dielectric measurements even with electrically conductive materials. This advancement overcame initial challenges and expanded DEA’s measurement capabilities.

Challenges and Development Efforts

The early stages of DEA implementation were marked by numerous trials and hands-on development efforts. Dr. Chaloupka recalls the intensive work required to enhance the functionality of DEA systems:

“I joined NETZSCH in the summer of 2016, where I got one hundred percent insight. That gave me the time and the chance to really have overnight shifts and, when nobody was in the office, to solder resistors, capacitors, to change the analyzer configuration, all those small kinds of things that are necessary to resolve all the challenges we still had to meet industrially applicable customer’s expectations. Based on the results, the firmware team needed to make changes to further improve. So it was a continuous level up on hardware and firmware side.”

This period of deep research and development was crucial for addressing technical challenges and improving the measurement systems. Collaboration within the team was vital, as was the development of correction algorithms to handle the parasitic effects of new sensor coatings.

Dr. Chaloupka further highlights a significant breakthrough moment:

“The Christmas time and New Year’s Eve 2015-2016, that was the time when I, day and night, was working on programming a correction algorithm to make it happen with the parasitic effect we created with the new coated sensors to make dielectric measurements with electrically conductive material possible.”

The relentless efforts of the NETZSCH and sensXPERT teams led to the successful adaptation of DEA technology for industrial applications, ensuring it was robust, reliable, and capable of providing accurate real-time data.

sensXPERT’s Complete Transformation of DEA Technology

In 2021, the strategic direction of dielectric analysis (DEA) technology took a significant turn with the founding of NETZSCH Process Intelligence GmbH (sensXPERT), a corporate venture by the NETZSCH Group. sensXPERT took DEA from a traditional laboratory-based tool to an integrated solution for real-time manufacturing processes. This marked the beginning of a new era in the evolution of DEA, emphasizing its application in dynamic industrial environments.

Dr. Alexander Chaloupka highlights the mission: “The vision was to embed DEA into real-time production environments, enhancing operational efficiency and quality control.” This transition was not merely about adapting existing technology but transforming it into a comprehensive system capable of revolutionizing manufacturing practices.

Acquiring a Data Science Team for Enhanced Data Visualization

A pivotal step in this transformation was the acquisition of a dedicated data science team. Traditional methods of analyzing DEA data were labor-intensive and limited in scope. The need for advanced data visualization and interpretation became apparent. Dr. Chaloupka notes, “At the time, we were analyzing the data by hand every time. There was no software analyzing dielectric data and transferring them into values like Degree of Cure and something else. We really needed to correlate it with laboratory results.”

Recognizing these limitations, sensXPERT invested in building a robust tech stack with extensive data science capabilities. This allowed for the development of sophisticated algorithms and visualization tools that could provide real-time insights into material behavior. The integration of machine learning models enabled the system to dynamically predict and adjust to changes in material properties, significantly improving process efficiency and product quality.

Tech Stack Development

Developing a comprehensive tech stack was crucial for the success of sensXPERT’s mission. This involved integrating cloud computing, advanced software solutions, and data analytics to create a seamless interface between the DEA equipment and manufacturing systems. Dr. Chaloupka explains, “When we started in 2016, we were a 100% hardware team, and now, with sensXPERT, we are, from my point of view, a 90% software team. The hardware now is very important to get the data and to make things visible, but then everything that is around is software, pure software. Data Science, Cloud, the software that is running on the system.”

This shift from a hardware-centric to a software-driven approach underscored the importance of real-time data processing and analysis, providing manufacturers with actionable insights and greater control over their processes.

Future Trends in DEA Technology

Looking ahead, several trends are poised to shape the future of DEA technology. One of the most promising developments is the implementation of high-frequency dielectric analysis, which offers new levels of technological capability. Marco Zier mentions, “Of course the high-frequency DEA will offer us a new level on the technology and application point of view. We will see a lot of additional stuff. We will monitor not just the phase transition; we will have a look inside the material composition… This will bring us a totally new view of the materials and their behavior.”

Moreover, the continuous integration of artificial intelligence and machine learning into DEA systems will further enhance predictive capabilities and process optimization. As sensXPERT continues to innovate, the potential for DEA technology to transform manufacturing practices across various industries remains immense, promising more efficient, reliable, and high-quality production processes.