The Impact of Electric Vehicles on Automotive Plastics

Electric vehicles (EVs) have rapidly evolved from niche products to mainstream transportation options. The first modern, mass-produced electric cars emerged in the early 2000s, and since then, advancements in battery technology, infrastructure, and consumer acceptance have significantly accelerated their adoption. Governments worldwide are promoting EVs to reduce greenhouse gas emissions and dependence on fossil fuels, resulting in substantial investments and incentives aimed at supporting this transition.

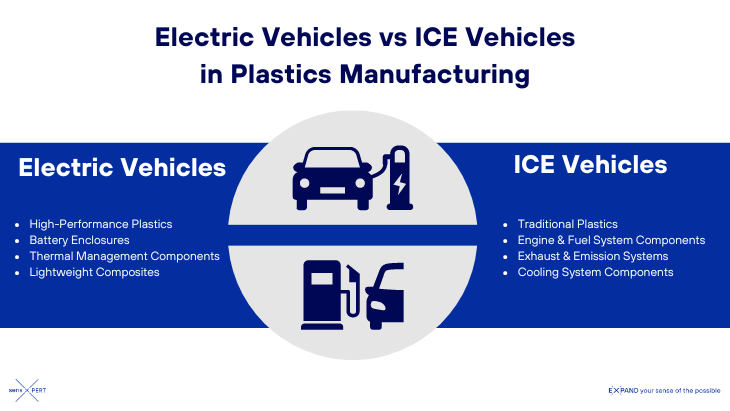

The automotive industry is experiencing a profound transformation as traditional internal combustion engine (ICE) vehicles give way to electric powertrains. This shift is not merely a change in propulsion technology but a comprehensive rethinking of vehicle design, engineering, and manufacturing. As EVs become more prevalent, their impact on various aspects of automotive production, including materials and processes, becomes increasingly significant.

This article aims to analyze the impact of electric vehicles on the automotive plastics manufacturing industry. It will explore how the growing popularity of EVs is driving changes in material requirements, production techniques, and innovation in plastics manufacturing. This article intends to help plastics processors in the automotive industry understand the evolving landscape and prepare for the challenges and opportunities presented by this shift towards electric mobility.

The Role of Plastics in Automotive Manufacturing

Plastics have long played a crucial role in the automotive industry due to their versatility, cost-effectiveness, and performance characteristics. In automotive manufacturing, plastics are used extensively to reduce weight, enhance fuel efficiency, and provide design flexibility. Components such as interior trim, dashboard panels, bumpers, and body panels are commonly made from various plastic materials. The lightweight nature of plastics contributes significantly to overall vehicle weight reduction, which is essential for improving fuel efficiency and reducing emissions.

Plastics also offer significant cost advantages over traditional materials like metal. They allow for complex shapes and intricate designs to be manufactured with ease, enabling automakers to achieve aesthetic and functional objectives without incurring excessive costs. Additionally, plastics provide excellent durability, resistance to corrosion, and impact resistance, ensuring long-lasting performance under various environmental conditions.

Common Types of Plastics Used

Several types of plastics are commonly utilized in automotive manufacturing, each selected for its specific properties and suitability for different applications. The following are examples of different polymer types and their applications in automotive manufacturing:

- Polypropylene (PP): Known for its versatility, low cost, and good balance of properties, PP is widely used in automotive components such as bumpers and interior trim.

- Acrylonitrile Butadiene Styrene (ABS): ABS is prized for its impact strength and heat resistance. It is commonly used to manufacture parts like dashboard components, bumpers, and fenders.

- Polyurethane (PU): PU is used in various applications, including seating, insulation, and exterior body panels. Its flexibility and cushioning properties make it suitable for both comfort and structural components.

- Epoxy Resins: Epoxies are known for their excellent mechanical properties, chemical resistance, and strong adhesive qualities. They are often used in coatings, adhesives, and composite materials for structural components such as body panels and chassis parts.

- Phenolic Resins: Phenolic resins offer high heat resistance and mechanical strength. They are commonly used in brake linings, electrical components, and under-the-hood applications where thermal stability is critical.

- Unsaturated Polyester Resins (UP): UPs are used extensively in composite materials due to their good balance of mechanical properties and cost-effectiveness. They are often found in exterior body panels, bumpers, and structural reinforcements.

Composite plastics combine different materials to enhance specific properties, such as strength, weight reduction, and thermal stability. These materials are increasingly important in the automotive industry, particularly with the rise of electric vehicles.

- Glass Fiber Reinforced Plastics (GFRP): GFRP composites are made by reinforcing plastic with glass fibers, providing high strength-to-weight ratios and excellent corrosion resistance. They are used in body panels, structural components, and battery enclosures.

- Carbon Fiber Reinforced Plastics (CFRP): CFRP composites offer superior strength and rigidity while being extremely lightweight. They are commonly used in high-performance applications such as sports cars, electric vehicle frames, and critical structural parts.

The selection of these materials is driven by their specific properties, which align with the functional requirements of different automotive components. As the industry transitions towards electric vehicles, the role of these plastics is evolving, driving the need for new materials and innovations in plastic manufacturing processes.

Changes in Automotive Design and Materials Due to Electric Vehicles

The transition from internal combustion engine (ICE) vehicles to electric vehicles (EVs) has introduced significant changes in automotive design and materials. One of the most notable structural differences is the placement and integration of the battery pack, which is often located in the vehicle’s floor. This design lowers the center of gravity, enhancing stability and handling, but it also necessitates robust protection for the battery pack, impacting the materials used in the vehicle’s construction.

Unlike ICE vehicles, which have complex engine compartments with numerous moving parts, EVs feature simpler powertrains. This simplicity allows for more flexible design approaches, such as optimizing aerodynamics and maximizing interior space. However, it also requires new materials that can support the different structural and thermal demands of EV components.

Increased Demand for Lightweight Materials

Reducing vehicle weight is a critical priority for EV manufacturers, as it directly affects the range and efficiency of the vehicle. Every kilogram saved in the vehicle’s weight can lead to significant improvements in battery performance and overall energy consumption. Consequently, there is a heightened demand for lightweight materials that do not compromise on strength, durability, or safety.

High-Performance Plastics: EVs require materials that can withstand higher thermal and electrical demands. High-performance plastics offer excellent thermal stability, mechanical strength, and chemical resistance. These materials are increasingly used in components such as electrical connectors, battery housings, and thermal management systems.

Composites and Advanced Materials: The use of composite materials, such as carbon fiber reinforced plastics (CFRP) and glass fiber reinforced plastics (GFRP), is expanding in the EV market. These composites provide high strength-to-weight ratios, making them ideal for structural components, body panels, and battery enclosures. Additionally, advanced materials like aluminum-plastic hybrids and multi-material laminates are being developed to meet the stringent performance requirements of EVs.

Thermal Management and Insulation Materials: Effective thermal management is crucial for EV performance and safety. Plastics with superior thermal conductivity and insulation properties are essential for managing the heat generated by batteries and electronic components. Materials such as thermally conductive polymers are being integrated into EV designs to enhance thermal management efficiency.

The shift to electric vehicles is driving significant innovation in the use and development of automotive plastics. As EV manufacturers seek to optimize performance, safety, and efficiency, the demand for advanced, lightweight, and high-performance plastics is set to grow. This evolution presents both challenges and opportunities for the automotive plastics manufacturing industry, necessitating continuous adaptation and innovation in materials and processes.

Impact on Automotive Plastics Manufacturing

This transition to EVs is also driving significant changes in the production processes used in automotive plastics manufacturing. To meet the new material requirements and design specifications of EVs, manufacturers must adapt their production techniques and integrate new technologies.

For instance, the increased use of high-performance plastics and composites necessitates advancements in molding techniques. Processes such as injection molding, compression molding, and resin transfer molding are being refined to accommodate the properties of advanced materials. These techniques must ensure precise control over material flow, temperature, and curing to produce high-quality components with complex geometries and tight tolerances.

Additionally, the integration of automation, robotics, and process control solutions in manufacturing processes is becoming more prevalent to enhance production efficiency and maintain high quality standards. Automated systems can handle complex assembly tasks, while in-mold process control solutions* can reduce cycle times and ensure consistent quality across large production volumes. This is particularly important when producing the intricate components used in EVs.

*Such as sensXPERT Insight

Moreover, the automotive industry is increasingly prioritizing sustainability, and this extends to the production of plastics. Manufacturers are exploring ways to incorporate recycled materials and bio-based plastics into their processes. This not only reduces the environmental impact of plastic production but also aligns with the broader sustainability goals of the automotive industry.

While innovation is necessary, the stringent performance requirements of EV components still require rigorous quality control and testing procedures. Material characterization technology – such as sensXPERT’s real-time, in-mold material characterization solution – and advanced testing methods are used to ensure that plastic components meet the necessary standards for strength, durability, and safety. These methods help identify potential issues early in the production process, reducing the risk of defects and failures in the final product.

The impact of electric vehicles on automotive plastics manufacturing is profound, driving the need for advanced materials, innovative production techniques, and enhanced quality control measures. Process engineers must stay ahead of these changes and continuously adapt to meet the evolving demands of the EV market. By embracing these innovations, the automotive plastics industry can play a crucial role in the successful transition to electric mobility.

Are you interested in learning more about the electric vehicle industry and the future of plastics manufacturing? Read ‘The Electric Vehicle Revolution and the Future of Automotive Plastics’