How Our Solution Works: Control Plastics Production Processes

To achieve consistent part quality – regardless of geographical location and seasonal conditions – processors everywhere are seeking out tools that increase stability to more reliably control plastics processes.

Given the number of materials and manufacturing processes currently used in this industry, many of the available tools designed to provide molders with more consistent control over their processes are very specialized. They are specialized in that they might be compatible with only a few polymer families or within a single molding process.

At sensXPERT, we set out to create a more flexible solution that is both process and material agnostic. We also developed a tool that could tell processors whether they are producing parts that are in spec and in line with qualitative requirements.

To develop this technology, we combined our material characterization expertise and a novel sensor system with machine learning algorithms to reliably visualize processes in real-time and forecast final part properties.

Meeting Tomorrow’s Process Control Needs Today

Today’s manufacturing environment heavily relies on in-house material characterization and modeling, process simulation, workforce experience, and material-supplier datasheets. It also demands high material, energy, and time investments from process set up to post-process quality assurance (QA) testing. This status quo also makes processors dependent on their suppliers’ own QA processes and reporting transparency.

Accordingly, processors are, in most cases, unaware of all the factors influencing material behavior during the production process. Additionally, there is typically a missing interface between manufacturing solutions and process efficiencies that impact the bottom line.

In attempting to meet today’s market demands for consistent process stability and part quality, processors are shifting towards the use and integration of Industry 4.0 technologies. One such technology is sensXPERT Digital Mold, a solution that provides real-time material and process transparency, as well as quality assurance per part produced based on critical measurement data such as degree of cure or crystallization, glass transition temperature, gel point, and flow behavior.

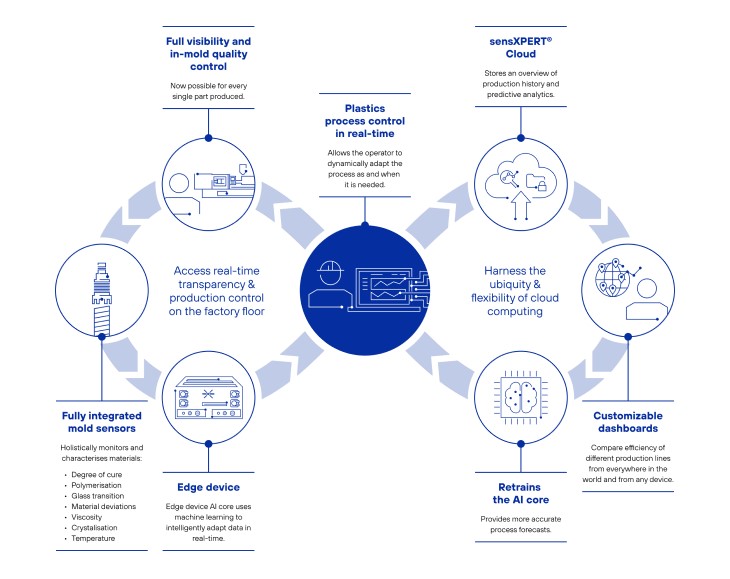

The sensXPERT solution helps molders access untapped potential in their processes and quantifiably increase productivity with material characterization and data analytics. In-mold dielectric sensors measure material behavior and send all collected data to an accompanying Edge Device (IPC).

Furthermore, machine learning algorithms on the Edge Device turn the data into quantifiable part quality measurements that are used to then forecast the outcome of a cycle. Additionally, the sensXPERT Digital Cloud Service ensures remote access to all sensXPERT-integrated manufacturing process data, regardless of geographic location.

Material Characterization Meets Machine Learning

sensXPERT is part of the NETZSCH Group, a global technology leader with over 50 years of experience in developing material characterization, testing equipment, and sensor technology. With over 4,000 employees across 36 countries, we have a broad understanding of and deep expertise in scientifically characterizing and quantifying material behavior.

However, with today’s demanding manufacturing and quality requirements, there is a greater need for tools beyond upstream and downstream characterization instruments. Processors need more insight into whether factors inside the tool or outside the press are causing processing conditions to change – even if such changes are subtle – as they could impact the quality and performance of final parts.

Accordingly, our division, NETZSCH Process Intelligence GmbH, was created to drive innovation and production efficiency by applying material knowledge and developing advanced Industry 4.0 process analysis technologies. This is especially crucial for processors that struggle to fill skilled positions with experienced workers.

Moreover, part manufacturers can access their processes’ hidden potential once they gain more consistent control over their cycles. Such potential includes decreased cycle times, energy consumption, scrap production, and cost of goods and services (COGS). The sensXPERT technology was designed to provide processors with faster, more efficient responses to the interplay of process parameters and material behavior.

About sensXPERT Digital Mold: Control Plastics Production

The sensXPERT system is a combination of several hardware and software components. Dielectric sensors and the sensXPERT Edge Device make up the hardware components. Two dielectric sensors are typically installed into one mold, with one placed beside a gate at the start of material flow and the other placed at the end of flow. The Edge Device is an IPC that sits outside of the machine to collect the data measured by the sensors within the tool, as well as other process parameters from the machine itself.

The sensXPERT software merges mathematical and physical/chemical models of polymer behavior with machine learning algorithms that constantly scan for patterns in the raw sensor data to generate predictive quality criteria. This is all visualized in the sensXPERT WebApp, an interface to the Edge Device, and the sensXPERT Digital Cloud Service.

The WebApp enables the Digital Cloud Service to communicate with the technician monitoring a given machine, without the need for a laptop and keyboard. The algorithms’ ability to parge large collections of data flowing in from machines across various production environments allows the system to become smarter over time.

Therefore, if the algorithms flag a set of data as unusual, the machine learning software alerts the local technician monitoring the machine that something in the process is out of the ordinary. It is then up to the operator to decide whether to act or not.

In the meantime, the machine learning algorithms are retrained according to the incoming data to continuously enhance process performance.

Advantages of sensXPERT Digital Mold

- Increases productivity by reducing cycle times

- Scrutinizes quality markers to alert processors of any material deviations in real-time

- Improves quality and reduces scrap by eliminating downstream (reactive) QA checks and moving them into the mold for real-time (proactive) quality assurance

- Provides full process transparency in a secure, data-rich environment

- Helps processors adapt to process shifts in real-time

- Lowers processing costs, energy usage, and waste

- Quickly generates a return on investment*

- A plug & play solution that does not require high installation costs and long process downtime, helping processors quickly increase their productivity

*Try out our ROI Calculator to determine your savings potential with sensXPERT