What Are Thermoplastics: Material Types and Processes

Thermoplastics are integral in various industries due to their versatility, recyclability, and adaptability. From the intricate components within automobiles to life-saving medical devices, thermoplastics are multifaceted polymers. Thermoplastics possess distinctive characteristics, notably the ability to melt and be molded when exposed to heat and revert to a solid state upon cooling.

This article outlines what thermoplastics are, their chemical composition, the numerous types of thermoplastics, properties, and applications, and the most popular thermoplastics processing techniques.

What Are Thermoplastics?

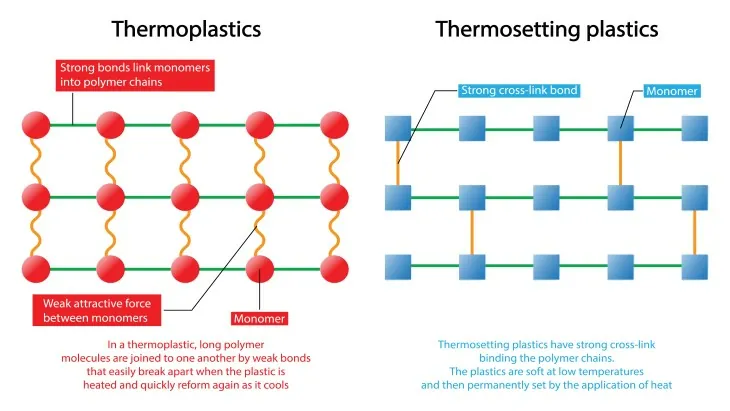

Thermoplastics represent a class of polymers characterized by their distinctive response to temperature changes. Unlike thermosetting plastics, which undergo irreversible chemical changes upon heating and cannot be re-molded, thermoplastics soften when exposed to heat and solidify when cooled.

This behavior allows thermoplastics to withstand multiple cycles of heating and cooling without sustaining major changes in their fundamental properties, which allows them to be easily recycled.

Understanding the Chemical Composition of Thermoplastics

Thermoplastics are formed through the process of polymerization, a chemical reaction during which small molecular units, known as monomers, join together to create long-chain polymers. One polymer chain comprises thousands of monomers.

Additionally, the arrangement of a thermoplastic’s molecular structure influences whether it is an amorphous or semi-crystalline polymer.

Amorphous Thermoplastics

These polymers have a disordered or random molecular structure without a well-defined, repeating pattern. In amorphous thermoplastics, the polymer chains lack specific long-range geometric order, which often results in materials that are transparent or translucent. These types of thermoplastics also generally exhibit higher impact resistance due to their lack of a semi-crystalline structure.

Amorphous thermoplastics find use in various applications, including transparent packaging materials, optical lenses, and consumer goods where impact resistance and transparency are crucial.

Semi-Crystalline Thermoplastics

In contrast to amorphous thermoplastics, semi-crystalline thermoplastics have a more ordered and structured molecular arrangement, resulting in the formation of crystalline regions within the material. The molecular arrangement of these polymers leads to the following properties:

- Strength and Rigidity: Semi-crystalline thermoplastics, such as polyethylene and polypropylene, tend to be stronger and more rigid due to the ordered arrangement of their molecules.

- Higher Meling Points: They often have higher melting points compared to amorphous thermoplastics

Semi-crystalline thermoplastics are commonly used in applications where strength, rigidity, and higher melting points are essential, which includes structural components in automotive parts, pipes, and other engineering applications.

Examples of Thermoplastics

While the two main thermoplastic polymer structures are amorphous and semi-crystalline, there are several popular types of thermoplastics, each with distinct properties and applications.

| Types of Thermoplastics |

|||

|---|---|---|---|

Type |

Acronym |

Properties |

Applications |

Polyethylene |

PE |

Semi-crystalline Good chemical resistance Flexible and lightweight |

Packaging materials Water pipes |

Polypropylene |

PP |

Semi-crystalline High strength and rigidity Resistance to chemicals and fatigue |

Automotive components Packaging materials |

Polyvinyl chloride |

PVC |

Amorphous Flexible or rigid, depending on form Chemical resistance |

Construction materials Pipes and fittings Medical devices – tubes and bags |

Poly(ethylene terephthalate) |

PET |

Can be amorphous or semi-crystalline Transparency (amorphous) Mechanical strength (semi-crystalline) |

Beverage bottles Textile fibers Films |

Polyamide |

PA – Nylon |

Semi-crystalline High tensile strength Good chemical resistance |

Textile industry Automotive components Dowels |

Polystyrene |

PS |

Amorphous Transparency Lightweight |

Packaging materials (including expanded PS) Disposable utensils |

Acrylonitrile-butadiene-styrene |

ABS |

Amorphous Impact resistance Good dimensional stability |

Consumer electronics Automotive parts Housings/casings/surface parts |

Polycarbonate |

PC |

Amorphous Transparency High impact resistance |

Optical lenses Eyewear, specifically protective eyewear/visors |

Poly(methyl methacrylate) |

PMMA |

Amorphous Optical clarity UV resistance |

Transparent plastics in optics and signage Acrylic glass |

Polyoxymethylene |

POM |

Semi-crystalline Low friction High stiffness and strength |

Precision parts in machinery Gears and bearings |

Poly(lactic acid) |

PLA |

Amorphous Derived from renewable resources Biocompatible |

Biodegradable packaging materials Disposable cutlery and plates Threads for medical sutures and implants |

Poly(phenylene oxide) |

(PPO) with High Impact Polystyrene (PPO+HIPS) |

Amorphous Good electrical insulator Impact resistance (HIPS component) |

Electronic components Automotive parts |

Polytetrafluoroethylene |

PTFE – Teflon |

Non-reactive Low friction High chemical resistance |

Non-stick cookware Seals and gaskets |

Poly(vinylidene fluoride) |

PVDF |

Semi-crystalline Excellent chemical resistance High thermal stability |

Chemical processing equipment Electrical insulation |

Polyetheretherketone |

PEEK |

Semi-crystalline High temperature resistance Excellent chemical resistance |

Aerospace components Medical implants |

Poly(phenylene sulphide) |

PPS |

Semi-crystalline Chemical resistance High temperature stability |

Electrical components Automotive parts |

Polyetherimide |

PEI |

Amorphous High temperature resistance Flame resistance |

Aerospace components Medical devices |

Polyethersulfone |

PESU, PES |

Amorphous Excellent chemical resistance High temperature stability |

Aerospace components Medical devices |

Polybenzimidazole |

PBI |

Amorphous Excellent thermal stability Flame resistance |

High-temperature applications (flame-resistant) Aerospace and automotive components |

Processing Thermoplastics

The processing of thermoplastics involves transforming raw polymer materials into a myriad of shapes and forms to meet the diverse needs of various industries. This process is marked by precision and adherence to specific manufacturing techniques to ensure that resulting products exhibit the desired properties and functionalities.

Injection molding and extrusion are the most popular thermoplastic processing techniques, making up about 80% of the thermoplastic manufacturing market.

Thermoplastic Injection Molding

This process entails injecting thermoplastic material into a mold cavity, where it solidifies to form the final product. Injection molding is favored for its ability to manufacture high volumes of complex components with exceptional repeatability.

The injection molding process begins with the feeding of thermoplastic pellets into a heated barrel. The material is melted and injected into a mold under high pressure. Once inside the mold, the material cools and solidifies, taking the shape of the mold cavity. Ejection mechanisms then release the final product, and the cycle repeats for subsequent production.

Injection molding is prevalent in the manufacturing landscape and contributes to the production of a wide range of products, including automotive components, consumer electronics, medical devices, and household items.

Thermoplastic Extrusion

Extrusion is another popular method of thermoplastic processing. This process involves the continuous shaping of thermoplastic materials by forcing them through a die to create a consistent profile or shape. Extrusion is generally suitable for producing long, uniform products with a constant cross-section, which ranges from simple pipes and tubes to complex profiles used in construction and manufacturing.

The process begins with the feeding of raw thermoplastic material into the extruder, a machine equipped with a rotating screw that transports and melts the polymer. The molten material is then forced through a die, determining the final shape. Post-extrusion, the shaped material undergoes cooling, sizing, and cutting to attain the desired dimensions and properties.

Extrusion is used in various industries, most notably in the production of pipes, tubes, sheeting, and profiles.

In previous articles, we discussed thermosets, elastomers, and composites.

If you are interested in hearing our experts discuss material deviations and production anomalies, as well as the ways to combat them, watch our free on-demand webinar on “Enabling Automated Quality Control in Composites for Less Scrap, Higher Yield”.