Trenchless sewer rehabilitation with UV

Material, technology, and latest innovations for reliable quality control and safety improvement

ProKASRO Mechatronik and NETZSCH Process Intelligence jointly release game-changing information on the latest technology, enabling the UV liner’s curing mechanism to increase performance.

The NO-DIG movement is widely spread, and trenchless sewer rehabilitation is a means to an end. The promising novel method renews damaged sewer pipes intending to restore sealing and regain stability. For this purpose, a plastic layer, the so-called liner, is installed as a new pipe wall.

The sewer shaft installation process requires an uncured state of the liners, which consist of glass-fiber-reinforced, poly-, or vinyl ester resin. It allows easy handling and correct applying the new shell to the existing sewer wall. With the assistance of UV lamps attached to sophisticated state-of-the-art robots, known as cores or chains, the liner cures.

In an after-construction-site-completion process, accessible peripheral samples experience testing in certified laboratories to determine characteristic values, such as residual styrene level and degree of cure.

Liners and its reaction

The plastic liner, usually styrene-containing poly or vinyl ester resin-impregnated glass fiber fabrics, is custom-made in wall thickness and length to meet the respective construction site requirements. Transported in secured packaging, the cured-in-place liners solidify, utilizing UV lamps.

The reaction mechanism is a radical polymerization process with UV light energy causing the initiator to decompose into reactive radicals. It further triggers a chain reaction in which the reactive radicals cause the monomers in the resin to chemically bond, known as a curing or crosslinking reaction. During the crosslinking process, the poly- or vinyl ester resin forms long-chain compounds, and the styrene provides the crosslinking, resulting in very high mechanical strength.

Around the technology

The technology consists of a rehabilitation vehicle, fully equipped to manage the job and likewise being the command center for the construction site. The vehicles range from 3.5t sprinter size to 18t trucks.

In addition to the UV-curing technology, the vehicles also include technology for work robots, milling exposure of inlet pipe joints and their joint sealing, and TV inspection systems for visual inspection of the rehabilitation section. The design of the UV lamp’s wavelength range matches the liner systems available on the market.

The truth behind commonly spread myths

UV radiation can only penetrate a few millimeters into the material, so thick liners do not cure entirely and remain soft in the area of the original sewer wall.

Indeed, UV radiation can only penetrate a few millimeters. Nevertheless, combining UV and thermal energy input is the decisive factor for curing thick liners. The UV light only initiates radical formation and triggers the chain reaction. Subsequently, the increased temperature keeps the chain reaction going, and the reactive radicals migrate through the liner and provide crosslinking. Therefore, UV cores with very high powers are not the solution for the higher penetration depth of UV light. However, with the higher temperature development, they ensure that the crosslinking reaction takes place sufficiently even in thick liners.

Some liner manufacturers’ UV initiators are incompatible with existing equipment technologies or malfunction.

Today’s conventional mercury steam lamps cover a broad spectrum with main intensity lines in the UV, visible, and infrared ranges. The lights are almost an all-purpose weapon for UV initiation, combining thermal energy to increase the reaction power. From a chemical point of view, all commercial available UV initiators, can be triggered by mercury steam lamps.

Is more really better? Often stated, the higher the temperature, the better!

The assumption is simply wrong! High temperatures often cause liner damage. Brittle effects, but even more harmful, is the negative impact on the protective film, causing it to stick to the liner while it needs to be removed after the curing process finishes.

The combination of UV initiation and the thermal influx decide over the liner’s cure and therefore its performace.

Liner testing in the lab

The liner lab testing has two main goals

(a) the achievement of sufficient mechanical strength and

(b) the ecological integrity of uncured chemical components.

Therefore, among other parameters, the values ‘residual styrene level’ and mechanical ‘E-Module’ are of primary interest. Inspection of processed liners is carried out by accredited testing laboratories, of which there are only a few in Germany.

Liner testing at the construction site

The call for on-site testing increases consistently. Climatic site-to-site influences, differing material behaviors due to a diverse liner manufacturer landscape, and other dominating factors, such as channel wetness, affect the curing behavior of plastics. A promising technology delivering both high sensitivity and a transportable setup is dielectric analysis (DEA). More than ten years ago, SBKS & Co. GmbH and NETSCH-Gerätebau GmbH, the market leader in thermal and dielectric analysis, conducted real-life tests with disposable sensors on the construction site to monitor liner curing.

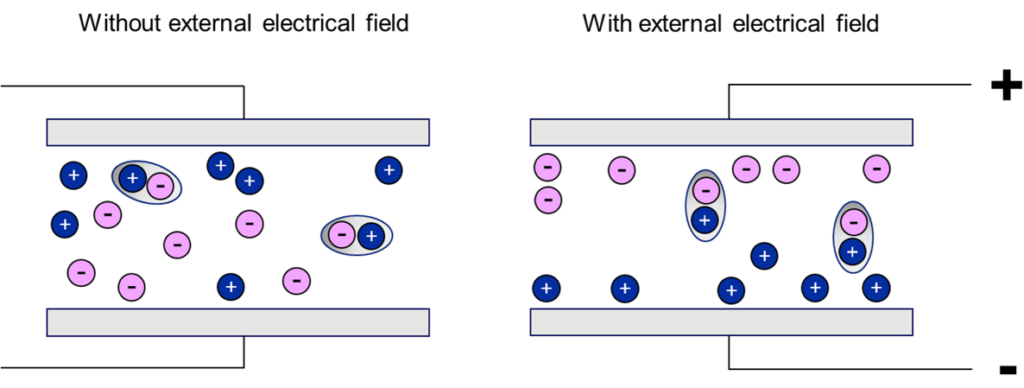

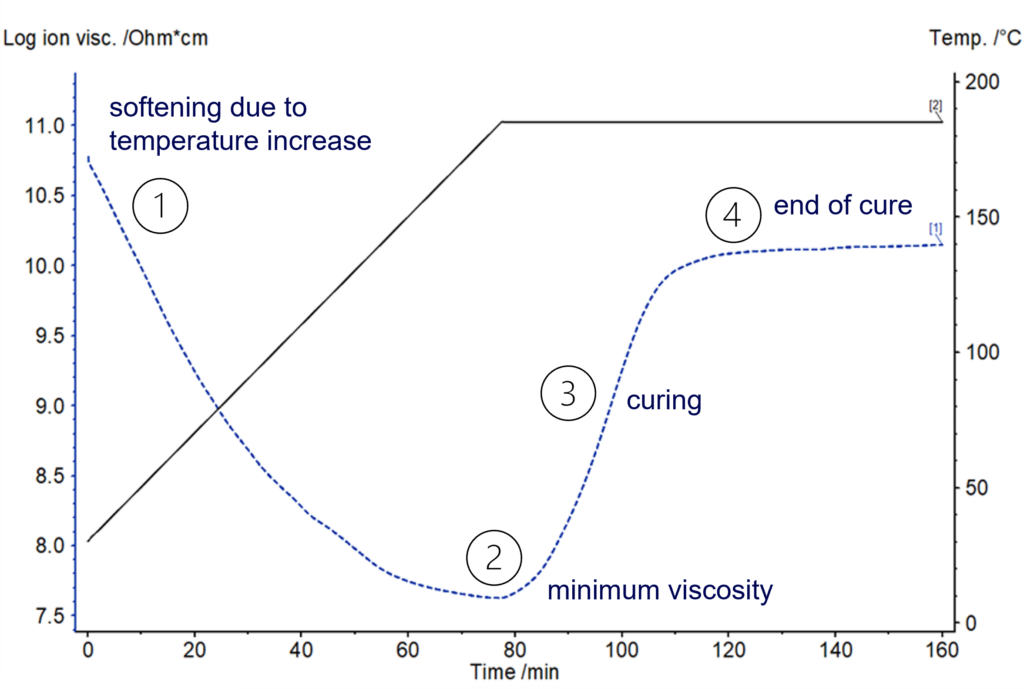

According to the measuring principle of dielectric analysis, the investigated sample is stimulated via a sensor by alternating voltage. The response behavior displays a current flow and the reaction time from excitation to the response.

As a result, the microscopic mobility of the plastic is measured, arising from the alignment of dipoles and the movement of smaller molecular groups. As the curing progresses, mobility decreases. The generated measurement data provide precise insight into the material behavior and previously inaccessible data.

Disposable DEA sensors give insights into material behavior and portability, but it sees limitations that challenge the technological suitability:

The measurement principle requires the investigative material to be directly in contact with the sensor. As a result:

- the sensors can either only measure into the duct at the peripheral area of a construction site within arm’s length, or

- have to be inserted during liner production, which would turn the manufacturing process upside down,

- the sensors only measure at specific points and would therefore have to be integrated into the liner in large quantities to obtain statistical significance along the rehabilitation route,

- the absolute measured values are strongly dependent on the moisture, the liner temperature and the fiber fraction content, which make data evaluation via absolute measured values difficult, not to say impossible.

As a conclusion of the manufacturing process and the handling of the liner, an only peripheral area is not representative of an entire rehabilitation channel. Moreover, the climatic conditions around the periphery differ from the conditions in the sewer.

A novel patented process opens up new monitoring possibilities

Due to the limitations of the existing dielectric measurement technology for on-site use in trenchless sewer rehabilitation, NETZSCH decided to develop a novel, no-contact sensor technology that monitors material and whose measurement signals are more independent of environmental influences.

Together with ProKASRO Mechatronik GmbH, NETZSCH Process Intelligence GmbH has patented a process that monitors the curing progress along the entire sewer rehabilitation channel and sends the information to the command center in real-time. It further enables the active and dynamic control of the core’s pulling speed based on the material’s curing progress to exploit the highest possible pulling speed and avoid overheating of the liner. Concurrently, the cured liner data measured in the channel allows correlation with quality assurance data such as the degree of cure, E-modulus and the residual styrene level.

The solution’s sensor and evaluation unit, named ‘sensXPERT Pipe’, is directly mounted on the UV cores while the data is transferred to the ‘third man’. Expanding the ‘third man’ as a system component that actively controls the core significantly reduces sudden leaps and makes the system accessible for retrofitting and new UV radiation systems of ProKASRO and its competitors.

Contact

ProKASRO Mechatronik GmbH

Teresa Jahn

E-mail jahn@prokasro.de

sensXPERT / NETZSCH Process Intelligence GmbH

Sabrina Fröhlich

Communication Manager

Phone +49 9287 919 185

E-mail sabrina.froehlich@sensxpert.com