Soaring Efficiency: How an Aerospace Leader Transformed Aircraft Production with sensXPERT

Key Facts

Market pressure places increasing strain on aerospace part manufacturers, especially in light of Industry 4.0. To keep up with current demands, a leader in aviation manufacturing collaborated with sensXPERT in hopes of increasing efficiency.

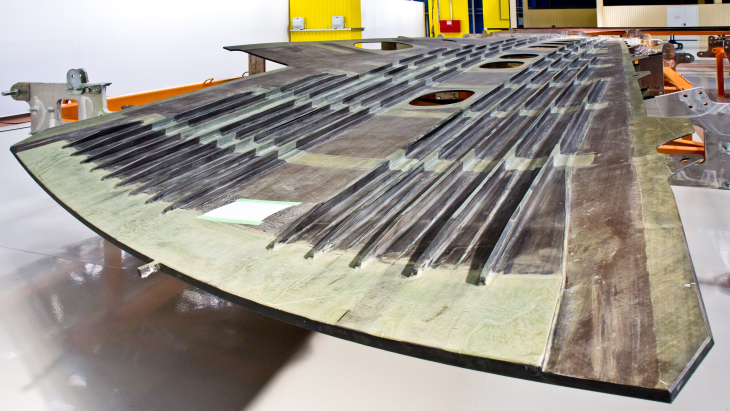

The aviation company produces fibre-reinforced composite parts used for fuselage support. Being a large and complex part, the lengthy production process is comprised of several steps. VARTM, cool-down periods, and autoclave curing to be exact.

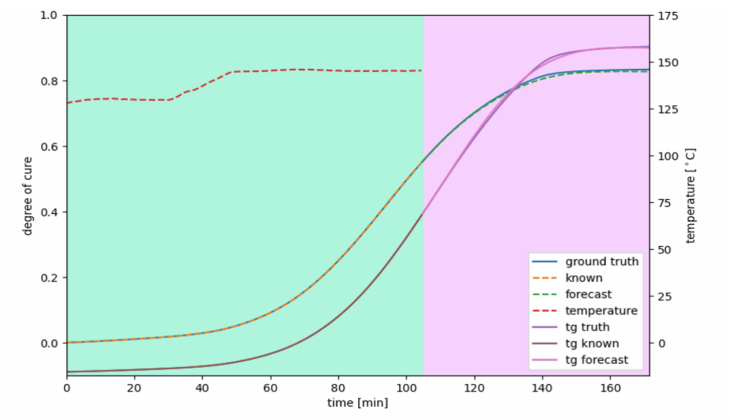

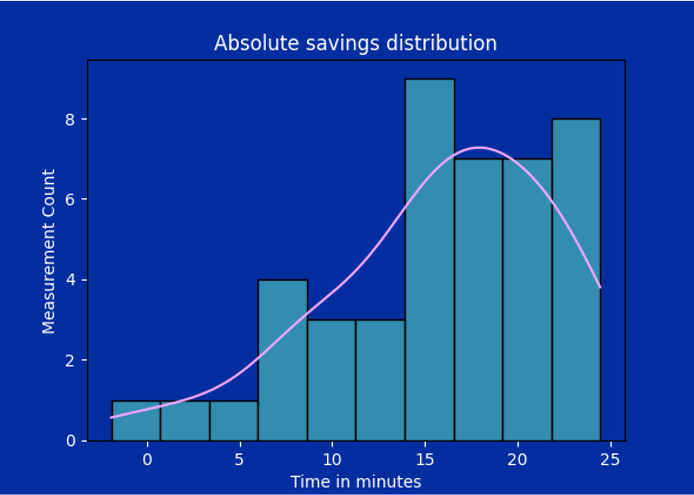

By implementing sensXPERT and digitizing their process, the aviation company gained insight into part performance forecasts, which allowed for part corrections prior to downstream quality assurance testing. Notably, only 50 minutes of measurement data was needed to predict the outcome of a cycle and optimize accordingly. A boost in process efficiency is just one of the advantages brought on by digitization in this case.

The aerospace industry is an ever-evolving sector characterized by innovation. Since the Wright brothers’ successful invention of the heavier-than-air craft, competition and a drive for advancement has made the industry a trailblazer in scientific and technological progress.

This progress can be simply exemplified by the expansiveness of the industry, with its global fleet expected to soar from 24,510 commercial aircraft in 2023 to a staggering 48,575 by 2042.

While these figures highlight the scale of the industry, a significant factor contributing to this expected growth is the large-scale production ramp-up planned by aviation OEMs to address their overflowing order backlogs. This ramp-up is driven by airlines’ efforts to meet the surge in consumer demand post-pandemic and to incorporate more fuel-efficient aircraft models into their fleets.

However, while air travel has recovered faster than aircraft production since COVID-19, this disparity has created mounting pressure on manufacturers. They must ramp up production while ensuring that each component meets the highest standards of quality and safety. Additionally, industry players are increasingly focusing on meeting sustainability goals. While CO2 footprint is a strong indicator, KPIs are set to reduce energy and to resourcefully use raw materials for scrap prevention. With the advent of novel processing technologies and software, data utilization has become significant and crucial in sustainability efforts. Simple measures like real-time cure control and understanding material behavior during processing can be taken, keeping the industry informed and aware of the latest trends. In this high-stakes environment, efficiency is key.

Unfortunately, increasing production efficiency proves challenging in an industry subject to heavy regulations and quality standards. To meet rigid safety requirements, manufacturers often rely on traditional processes like autoclave curing, including long-cycle safety buffers, to ensure full component curing. In turn, the long cycle times, high energy consumption, and lower throughput hinder efficient manufacturing and the goal of ramping up production.

The aerospace industry leader in this case study has always been at the forefront of advancements in aviation manufacturing. Therefore, in its continuous pursuit of innovation, production optimization, and efficient manufacturing, the aerospace company approached NETZSCH Analyzing & Testing in 2016 to investigate the possibility of in-line material characterization.

What began as a straightforward request to improve production monitoring unexpectedly blossomed into a pioneering collaboration, pushing the boundaries of aerospace manufacturing.

This is the story of how a leader in aerospace manufacturing integrated sensXPERT Insight, utilizing real-time cure monitoring and process control to revolutionize its process, slash cycle times, and ensure impeccable component quality. Accordingly, the aviation company is leading the way in establishing new industry standards.

The Company’s Manufacturing Process

In producing load-bearing aircraft components, the aviation manufacturer employs advanced techniques and high-performance materials to ensure the highest standards of quality and safety.

The process begins with selecting composite materials, primarily carbon fiber-reinforced polymers (CFRP), due to their exceptional strength-to-weight ratio and durability. The chosen carbon fibers are woven into fabrics and then pre-impregnated with RTM6-1, a type of aerospace-grade epoxy known as Hex Flow® by Hexcel Corp. This combination forms the prepreg materials essential for the component’s structural integrity.

The manufacturing process is characterized by the meticulous use of vacuum-assisted resin transfer molding (VARTM) and subsequent autoclave curing. During VARTM, dry fiber preforms are precisely cut and manually placed into a specialized mold. The mold is then sealed, and a mixture of epoxy resin and hardener is injected under vacuum. This process typically takes up to 150 minutes, with a slow cure at low temperatures to prevent deformation and stress. In the process at hand, the aviation manufacturer aims for a target Degree of Cure (DoC) of 80%, which is critical for the component’s preliminary structural properties.

Following the VARTM process, the parts undergo a critical cool-down period, gradually decreasing from approximately 150°C to a demolding temperature of about 50°C. This period allows the parts to cure, ensuring they reach a DoC of at least 80% before removal from the mold.

The final stage involves autoclave curing, a step of great importance. Here, the parts are subjected to controlled pressure and temperature cycles to achieve a secondary DoC target of around 95%. This step is vital for finalizing the component’s mechanical properties and ensuring long-term performance.

The aerospace company has always upheld rigorous standards to ensure each component’s quality and safety. To stay at the forefront of the industry, it continuously seeks opportunities to optimize its production processes by closely examining every aspect to identify potential efficiency improvements.

Identifying Inefficiencies

With this commitment to continuous improvement, the aviation manufacturer identified a few key optimization opportunities in its manufacturing process that promised tangible efficiency.

One of the key inefficiencies identified in its manufacturing is the long cycle times and safety buffers required for the adequate curing of composite components. While these extended times are necessary to meet its DoC targets, they significantly impact energy consumption and production costs.

Additionally, closed mold processes create a lack of transparency on real-time material behavior, which presents challenges in determining optimal cycle times for demolding. This often results in conservative estimates that prolong the process.

Furthermore, while the manufacturer has been successful in its established processes, the landscape in which it operates is shaped by its internal processes and external regulatory frameworks.

Navigating Regulatory Standards: EASA

One of the key regulatory bodies influencing the industry is the European Union Aviation Safety Agency (EASA). EASA’s regulations are pivotal in setting safety standards and compliance requirements, directly impacting aviation manufacturers’ operations and production strategies.

In their quest to meet EASA’s stringent standards, aviation manufacturers must adhere to the agency’s regulations when implementing new processes or enhancing existing ones with new technology. EASA’s mandate covers all aircraft manufacturing and maintenance parts, from engines to avionics and structural components. Each part must be certified to meet specific safety standards, a process that includes comprehensive documentation to trace the part’s history back to its manufacturer. This elaborate process ensures the authenticity and integrity of each part, a testament to EASA’s commitment to safety and quality.

Additionally, the EASA Part-21 regulation explicitly governs the production of aircraft parts, setting out detailed requirements for design verification, production methods, and quality assurance.

Solution Background: Optimizing the Manufacturing Process

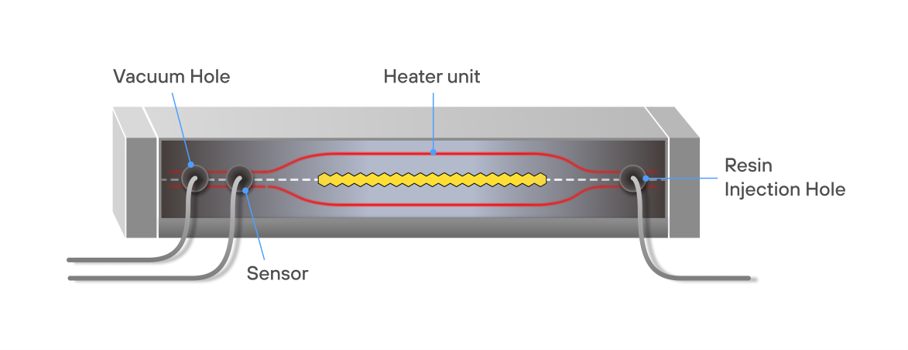

In 2016, faced with the challenge of meeting stringent EASA standards while improving production efficiency, the aerospace leader took a proactive step. The company initiated a collaboration with NETZSCH Analyzing & Testing, focusing on in-line material characterization to optimize the curing process of its composite components. The partnership began with the early installation of a dielectric analysis (DEA) system in one of the aviation manufacturer’s autoclave processes. This early installation was a crucial step in providing real-time data on material parameters such as DoC, temperature, and viscosity during the curing process, all essential for producing high-quality, safe components as mandated by EASA.

Over the next few years, from 2016 to 2020, the NETZSCH Analyzing & Testing team refined the DEA technology. The key objective was to ensure that the monitoring system provided precise and reliable data, enhancing sole measurement data aligned with the aviation industry’s quality standards.

In 2021, NETZSCH took a significant step by establishing NETZSCH Process Intelligence GmbH (sensXPERT). The novel venture is dedicated to advancing process monitoring capabilities, leading to the creation of sensXPERT Insight. The system, known for its adaptability to various manufacturing processes, was designed to provide comprehensive in-mold material characterization, capable of withstanding various pressures and temperatures. It is suitable for reaction injection molding, VARTM, and autoclave curing, showcasing its versatility.

After integrating sensXPERT Insight into its VARTM process, the aviation manufacturer could access a plethora of in-mold process and material insights, including DoC, percent polymerization, glass transition temperature (Tg), and viscosity. The sensXPERT solution’s real-time data acquisition and material characterization capability meets the quality criteria set by both the aerospace leader and organizations like EASA.

By conducting real-time in-mold material characterization during the VARTM process, this advanced monitoring solution enabled precise control over the curing process. It allowed for automated adjustments that stopped the cycle times at the optimal point of cure (80% DoC). This optimization was critical in producing high-quality outputs while significantly enhancing efficiency.

One of the solution’s most notable outcomes was the reduction in cycle times. By accurately identifying the optimal point of cure, the aerospace company could decrease the duration of its VARTM cycle time by an average of 13% ± 5.3 % and a maximum of 20%.

Additionally, the improved process transparency allowed for real-time adjustments that reduced reliance on conservative safety buffers. Another significant benefit was increased energy efficiency. By minimizing the time components spent in the curing process, the aviation manufacturer achieved up to a 23% increase in energy efficiency, thus lowering operational costs and the overall environmental impact of the manufacturing process.

Implementing sensXPERT Insight significantly improved the company’s CFRP component production processes.

A seasoned composite leader at the aerospace company, summarizes the sensXPERT technology’s capabilities as follows:

“The combination of reduced cycle times, increased energy efficiency, and improved process transparency underscore the value of real-time monitoring and dynamic adjustments in achieving operational excellence. It is an invaluable contributor to what our company aims to be, the leader in the aerospace industry.”

The collaboration between this aerospace manufacturer and sensXPERT is continuous and has now shifted from a pre-production setup to serial manufacturing.

With these advancements, the future looks bright for all aviation manufacturers as they adopt real-time process control innovations to enhance efficiency, sustainability, and competitiveness in the industry.

Interested in Learning More?

Quality and Efficiency in Aviation: Leveraging Dielectric Analysis for Process Control

Watch an exclusive interview-style webinar with sensXPERT and Testia (an Airbus company) to uncover how dielectric analysis evolved into an essential tool for real-time quality control in aviation manufacturing. Learn from experts how automated data analysis and process adjustments are helping manufacturers meet strict industry standards while optimizing efficiency.

Watch the free on-demand webinar today!