15 – 18 April 2025 in Shenzhen, China

Join us at our first exhibition in China

Chinaplas 2025 emphasizes sustainability, innovation, and smart manufacturing in plastics and rubber. It showcases eco-friendly materials, advanced technologies, and automation, highlighting trends like circular economy and digitalization. The event fosters industry collaboration and addresses global challenges through cutting-edge solutions.

Meet us in Hall 10 Booth A05

We are a NETZSCH company

Who is sensXPERT?

Founded in 2021, sensXPERT is a technology brand of NETZSCH Process Intelligence GmbH, a corporate venture of the NETZSCH Group. Headquartered in Selb, Germany, sensXPERT builds on over 50 years of materials expertise and experience in sensor technology and is supported by a group-wide talent pool of more than 4,000 employees.

More Information

What do we offer?

sensXPERT provides data-driven manufacturing solutions that help customers in the plastics processing industry increase their productivity in real time. The company combines advanced measurement hardware and material science with the artificial intelligence of machine learning software to characterize material behavior in sync with the machine and cavity, increasing process efficiency, reliable reproducibility and consistent product quality by detecting, evaluating and controlling all critical influencing factors. The intelligent technology supports thermoset, thermoplastic, composite, and elastomer processing techniques.

Our products and solutions

sensXPERT Inisght

In-Mold Cure Monitoring

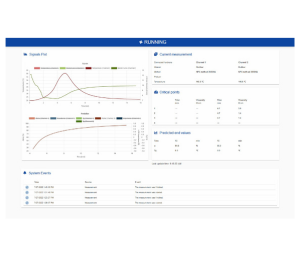

sensXPERT Insight is an end-to-end, integrated Equipment-as-a-Service solution for the plastics manufacturing industry. Dielectric sensors are the heart of the system. Data collected by the sensors are transferred to the sensXPERT edge device. The sensXPERT technology excels in its mathematical and physical/chemical models of material behavior and machine learning algorithms that constantly scan incoming data for patterns and deviations in the background. The algorithms translate the raw sensor data into predictive quality criteria, feeding them back to technicians, monitoring a given machine and process via a web app. The display of all data in the sensXPERT cloud application allows plastics manufacturers to control and compare manufacturing processes across different production sites. Companies benefit from process transparency and digital component mapping. Economically, the solution achieves to decrease of up to 50% of existing scrap, 23% in energy savings and 30% cycle time reduction.

More Information

Contactless Cure Monitoring

Our new contactless measurement technology leverages high-frequency dielectric analysis (HF-DEA) to monitor curing behavior in real time. By analyzing the dielectric properties of materials—such as permittivity and conductivity—it detects molecular changes during the curing process without physical contact. This allows accurate measurements through composite structures up to 40 mm thick, overcoming the limitations of embedded sensors or coupling media in complex geometries and open tooling setups.

Proven Success: Real-World Impact

Discover our customer success stories

With our innovative solution, we revolutionize manufacturing processes across various industries. The sensXPERT technology supports thermoset, thermoplastic, composite, and elastomer processing techniques. We achieved significant cost savings in their manufacturing operations for ZF, NETZSCH, and a leading aviation manufacturer. See for yourself.

Discover