Revolutionary sensor technology wins major industry award

AVK honours the data-driven production solution for the plastics industry: sensXPERT Digital Mold

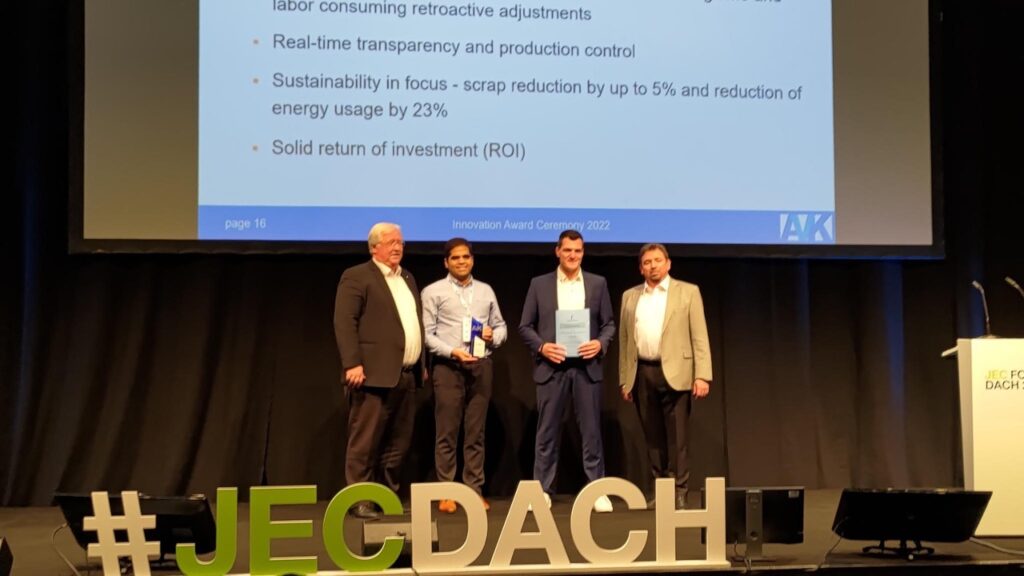

Augsburg, Deutschland, 29. November 2022 – Only two months after its international launch event, sensXPERT received the Innovation Award of the Federation of Reinforced Plastics (AVK) for its Digital Mold product.

The AVK is one of the largest associations in the field of composites in Europe. One aim of the Innovation Award is to promote new products and applications made of fibre-reinforced plastics as well as new processes for manufacturing these FRP products. A special focus in the selection of the award winners is on the aspect of sustainability.

The award went to sensXPERT for its innovative solution for optimising processes and increasing efficiency in the production of thermosets and fibre composites – by means of material and process data analysed in real time. The intelligent manufacturing technology supports various production processes such as reactive injection moulding, resin transfer moulding (RTM), compression moulding and autoclave curing. The combination of sensors and machine learning for machine- and cavity-synchronous material characterisation detects and controls all necessary influencing factors in real time. Process reliability is thus improved.

The AVK recognised the sensXPERT technology with this year’s awards in the category “Processes and Procedures”. sensXPERT founder and CEO Dr. Alexander Chaloupka proudly received the AVK award and said: “We are very proud to hold this award in our hands. It shows that we were able to convince the jury with our holistic approach. We will continue to work on making manufacturing processes more sustainable and efficient. This can only be achieved through a collaborative partner network, through which the knowledge that our customers need is digitalised and made available as a support tool. We would also like to take this opportunity to thank all our partners who have accompanied us on our journey so far and without whose support the ongoing development of sensXPERT would not have been possible”.

sensXPERT Digital Mold expands production capacities

At the Australian wheel manufacturer Carbon Revolution, sensXPERT Digital Mold is having a significant impact on productivity and quality. In order to achieve the productivity increase Carbon Revolution is aiming for, their HP-RTM lines are equipped with sensXPERT technology. This integrates downstream quality control into the production process. This significantly streamlines the multi-stage production process, minimises fluctuations and makes the process safer and more sustainable. In this way, the company expanded its production capacity to meet the increasing demand for carbon rims.

At NETZSCH Pumps & Systems, the technology is used to optimise the production of stators made from an elastomer. “We see a significant reduction in cycle times through the use of the new technology. This AI-based technology perfectly supports our efforts to further automate and digitalise our value chain,” explains Jens Heidkötter, Managing Director at NETZSCH Pumps & Systems. sensXPERT is also used in the aviation industry. As part of the ongoing collaboration, the AIRBUS R&T Composite Team is using the solution with various materials in different process scenarios. Crucial parameters such as the degree of curing and the glass transition temperature are recorded in accordance with highly sensitive state-of-the-art laboratory measurements.

Contact

sensXPERT Sabrina Fröhlich Communication Manager Phone +49 9287 91918 5 E-mail sabrina.froehlich@sensXPERT.com