Process Engineer

Maintaining a fully optimized process is vital, especially if you’re the person responsible for ensuring all quantity and quality targets are met. For any process engineer, this requires a vast knowledge of the various production processes and exceptional organizational skills. Essentially, you need to know exactly what’s called for to keep things running smoothly – right from when the material goes in, up until the final manufactured part comes out. For this reason, sensXPERT is the ideal solution – offering various features that not only keep scrap production low but also help you manage a genuinely efficient process.

sensXPERT features designed for you

Understanding the challenges you face

sensXPERT is designed to target a whole host of challenges faced by the plastics manufacturing industry. But let’s focus on the pain points that you may recognize in your own day-to-day work environment:

Top benefits worth considering

Explore real-world use cases for sensXPERT

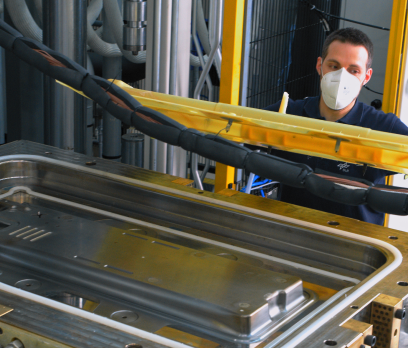

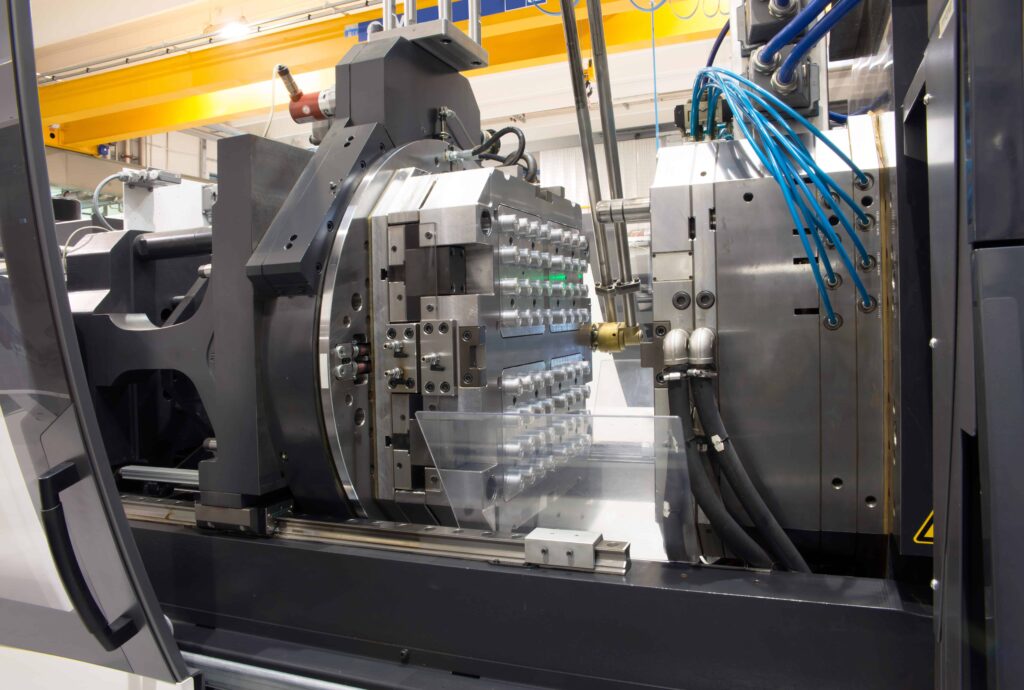

Improving in-mold transparency in the electrical encapsulation industry

Find out how two companies successfully used sensXPERT on their reaction injection molding processes to boost in-mold transparency and reduce scrap production rates.

Find out more