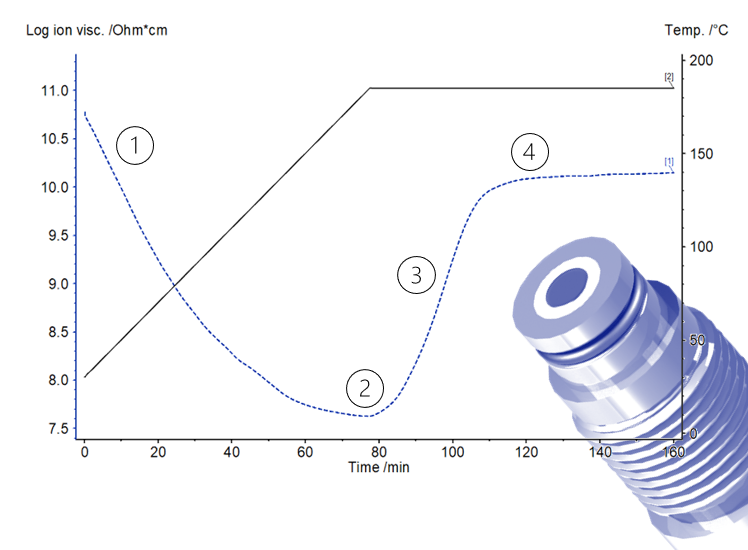

In-mold dielectric analysis data (DEA)

The potential for raw material deviations during part production is generally unavoidable due to a lack of process transparency. Moreover, influencing factors are random at best and can range from fluctuating humidity and ambient temperatures to raw material aging and storage conditions.

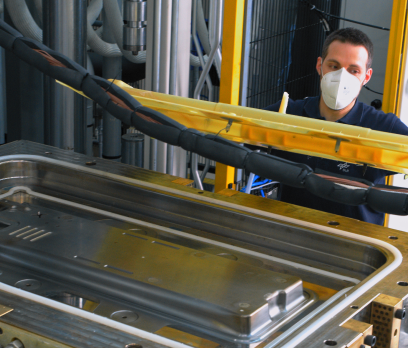

The power of sensXPERT’s technology lies in its unique ability to intelligently monitor and adapt to these many complex variables in real-time. The starting point here is sensXPERT’s use of dielectric analysis (DEA), which is carried out using sensXPERT’s material characterization sensors.

How it works

Relevant Industry Challenges

To understand the potential of in-mold dielectric measurements, it is important to address the various industry challenges these measurements help combat. Below we outline a few challenges or pain points that you may recognize from your production:

Benefits of In-Mold Dielectric Measurements

Explore real-world use cases for sensXPERT

Improving in-mold transparency in the electrical encapsulation industry

Find out how two companies successfully used sensXPERT on their reaction injection molding processes to boost in-mold transparency and reduce scrap production rates.

Find out more