The UV-Cured-In-Place-Pipe Market – An industry in transition

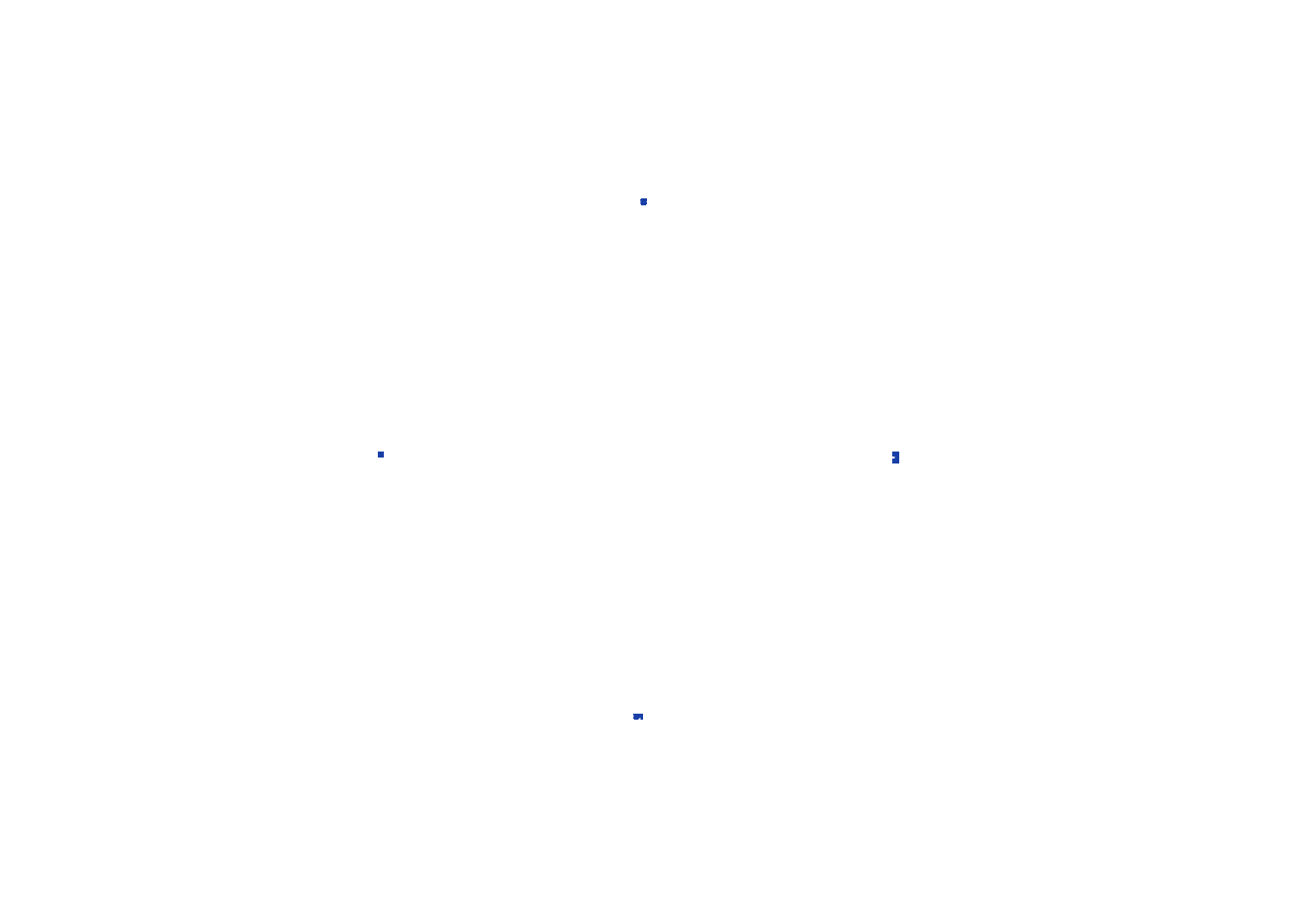

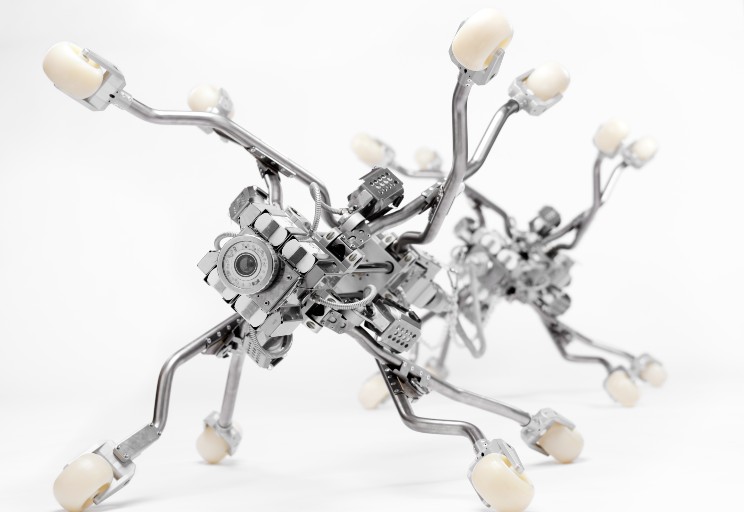

Today’s sewer rehabilitation market, using plastic liners, faces severe challenges in controlling the entire curing process. However, the increasing UV-CIPP acceptance builds the foundation for the soon-to-be-rolled-out innovative and transformative technology. With its pending patent, the sensXPERT product delivers a sustainable solution, controls the liner’s curing, enhances the efficiency on the construction site, and controls the quality at every point during the curing process. This novel and process-disruptive solution can monitor the curing of the material along the entire length of the sewer. It measures non-invasively and therefore has no negative impact on the liner.

sensXPERT enabling the UV-CIPP Market

Solution in a nutshell