Taking Control of Quality: How Process Control Optimized In-Situ PA6 Polymerization

Key Facts

Quality assurance and process efficiency is essential to meeting industry standards and enhancing credibility.

A large plastics manufacturer implemented sensXPERT Insight in their in-situ polymerization of PA6 to increase production efficiency, quality monitoring, and process control.

By integrating sensXPERT into their production, the company was able to cut down their cycle times by 12.5% and consistently produce optimal parts.

Quality assurance is essential in any manufacturing landscape, especially when supplying industries in which safety and performance are of the utmost importance; think automotive, aerospace, and medical. Besides guaranteed product performance and safety requirement adherence, quality assurance measures permit manufacturers to meet industry standards and regulations, as well as attain certifications to enhance credibility.

With quality assurance being a major driver for most manufacturers, a large plastics production company approached sensXPERT to optimize their processes, increase production efficiency, enhance quality monitoring, and introduce greater control in their cycles.

Serving numerous industries, from the automotive to the medical sectors, this large plastics manufacturer strives to supply their customers with parts of the highest quality. Therefore, quality testing and monitoring are key at every stage of their production – from acquiring raw materials to shipping products. For this reason, the company consistently seeks new possibilities to propel their quality assurance and production performance

Material and Process Insights

As a part of their product portfolio, the company manufactures large, thick parts through the in-situ polymerization of PA6.

Polyamide 6

PA6, also known as polyamide 6 or nylon 6, is a versatile semi-crystalline thermoplastic polymer with a wide range of properties that make it a valuable material for different applications. It is produced through the polymerization of caprolactam, a cyclic aliphatic amide. PA6 is characterized by its exceptional mechanical properties, including high tensile strength, impact strength, and wear resistance. It also exhibits good fatigue resistance, dimensional stability, and low moisture absorption.

Moreover, PA6 is relatively easy to process, making it a cost-effective material for mass production. PA6 is a common choice for applications requiring high mechanical performance, such as gears, bearings, and machine components. Its good chemical resistance makes it suitable for applications in the automotive, electrical, and aerospace industries.

In addition to its fundamental properties, PA6 can be modified to enhance specific characteristics by employing different techniques, such as blending with other polymers, adding fillers or reinforcements, and incorporating additives. These modifications can tailor PA6 for specific applications, such as increasing its stiffness, flame retardancy, or temperature resistance.

What is in-situ polymerization?

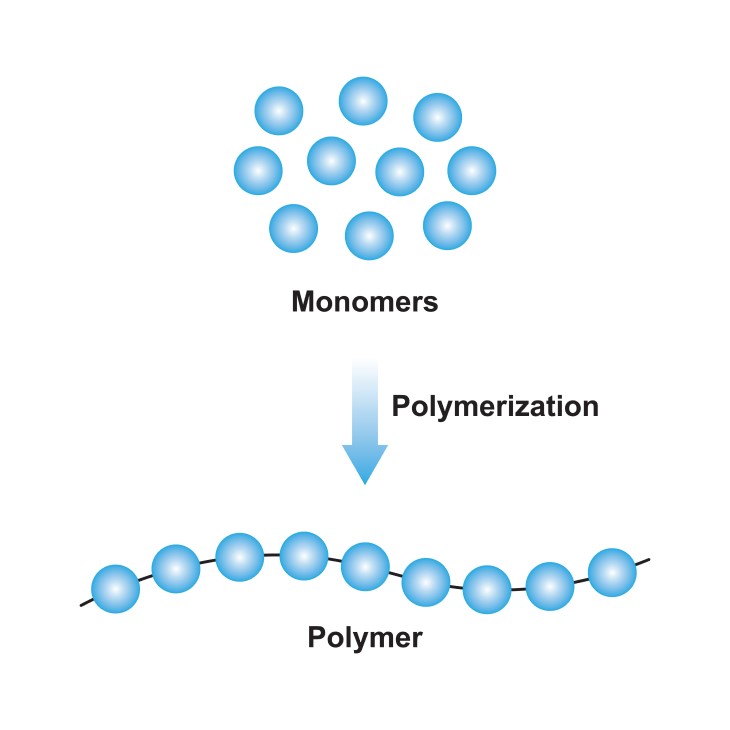

Polymerization is a fundamental process in macromolecular chemistry where small molecules called monomers combine to form long chains called polymers. These polymers exhibit a wide range of properties, making them essential materials for various applications, from construction to electronics.

Traditional polymerization methods involve mixing monomers and initiating the polymerization reaction in a separate vessel. However, in-situ polymerization offers a unique approach by synthesizing polymers in a mold to directly obtain a shaped part.

In-situ polymerization is the initiation and propagation of a polymerization reaction within a specific environment. The process involves introducing monomers, initiators, and other reaction components into a mold, triggering the polymerization reaction, and allowing the polymer chains to grow and form within the designated structure.

This direct integration of polymerization into the final application creates a more efficient and cost-effective approach for tailored materials with optimized performance for various applications.

In-situ polymerization offers several advantages over traditional polymerization methods, including:

- Tailored properties: In-situ polymerization enables the formation of polymers with specific properties by carefully selecting the monomers, initiators, and catalysts. The process also typically achieves high molecular weight, leading to the processing of very strong and tough material.

- Ease of flow

- Formation of complex structures: In-situ polymerization can be used to create intricate structures.

Additionally, the versatility of in-situ polymerization has led to a wide range of applications in different fields:

- Automotive Manufacturing: Producing lightweight and durable thermoplastic composite components for car interiors, exteriors, and structural components

- Aerospace Manufacturing

- Wind Power: Large thermoplastic composite wind turbine blades

Molding Nylon 6

In the case at hand, the company melts down caprolactam monomers in a dosing and mixing unit and incorporates additives in it at a temperature of about 100°C to 120°C. The monomers are then pumped into a mold that is set to 160°C.

Once the material is pumped into the mold, the polymerization reaction is initialized due to the mold’s elevated temperature. During production, the material is allowed about 16 minutes of reaction time. The top of the mold is then lifted, and the part is moved into an oven, in which it gets post-cured.

Prior to their integration of sensXPERT Insight, this process had been highly stable and did not produce any scrap. However, the company’s collaboration with sensXPERT highlighted an opportunity to increase production efficiency, while monitoring in-mold material behavior and quality outcomes.

You can read about the sensXPERT Insight solution here.

Collaboration Outcomes

With two dielectric sensors integrated into the top plate of the mold, sensXPERT’s sensors were ideally positioned to monitor and measure the PA6 behavior as it was pumped into and began polymerizing in the mold.

Overall, sensXPERT analyzed 178 production cycles of different lengths to collect data and develop a machine learning model. After collecting all the cycle data, sensXPERT’s data science team conducted a multi-dimensional analysis to make a classification of the different monitored features – for instance, all parts that did not reach sufficient strength for their subsequent handling were clustered together. The data science team then began building the machine learning model using a train-test split, after which the resulting model successfully clustered the cycles according to their outcomes.

sensXPERT determined that a cycle time of up to 11 minutes consistently leads to the production of unsuitable parts. However, cycles that reached 14 minutes consistently produced optimal parts. Therefore, sensXPERT enabled the company to cut down their cycle times by 12.5%.

Increased Production Efficiency and Quality Monitoring

By measuring in-mold material behavior and utilizing personalized machine learning models, sensXPERT accurately forecasts process outcomes, which enables dynamic process adjustments to ensure the highest quality per part produced.

As was the case with this company, sensXPERT’s process control solution aids manufacturers in discovering efficiency and optimization opportunities in production. sensXPERT also augments quality monitoring possibilities by making in-mold processes transparent.

Overall, sensXPERT enables manufacturers to decrease their scrap rates, increase energy savings, and reduce cycle times for more efficient, cost-effective production.